How Can You Determine the Right Size and Pressure Rating for Your Air Hose & Fittings?

2025.05.19

2025.05.19

Industry news

Industry news

When selecting AIR HOSE & FITTING, it is critical to ensure that their size and pressure rating are appropriate, which is not only related to the performance of the equipment, but also involves safety and efficiency. The correct selection of air hose size and pressure rating can avoid system failure, performance degradation, and even potential safety hazards. It is important to understand how to choose the right air hose and accessories based on actual needs.

The size of the air hose determines the amount of air flow. The inner diameter (ID) of the air hose is a key factor affecting the flow rate. Too small an ID will restrict air flow, resulting in insufficient air supply to the equipment, which will affect work efficiency and may even cause equipment damage. Although air hoses with too large an ID can provide more air flow, they will increase energy consumption and reduce the efficiency of the system. Choosing the right ID is crucial to ensure that the air hose system operates efficiently.

The length of the air hose is also an important factor. Long air hoses will cause increased friction losses in the air flow, which will affect the flow and pressure of the air. When choosing the air hose length, it must be determined according to the actual needs of the system. Generally speaking, longer air hoses may require the selection of larger diameter air hoses to offset friction losses. To ensure unimpeded airflow, it is best to choose the appropriate air pipe size and length according to the air flow required by the equipment and system.

In addition to size, the pressure rating of the air pipe is also crucial. The pressure rating (maximum working pressure, MWP) of the air pipe determines the maximum working pressure it can withstand. If the pressure rating of the air pipe and accessories is not selected properly, it may cause system leakage or even safety accidents such as bursting under high pressure. When selecting air pipes and accessories, it is necessary to ensure that their maximum working pressure is higher than the maximum pressure that the system may reach. To ensure safety, it is generally recommended to select air pipes and accessories with a certain safety margin, and their pressure rating should be more than 25% higher than the maximum pressure of the system.

When choosing the appropriate pressure rating, in addition to understanding the maximum working pressure of the system, it is also necessary to consider the impact of the actual use environment. Temperature changes will affect the pressure rating of air pipes and accessories, especially when used in high or low temperature environments. The increase in temperature will cause the strength of the material to decrease, which may cause the pressure rating to drop. When selecting air pipes and accessories, in addition to considering pressure, it is also necessary to consider the impact of temperature changes on their performance to ensure the safe operation of the system under different working conditions.

The matching between air pipes and accessories is also an important part of ensuring the efficient operation of the system. The inner diameters of the air pipe and accessories must match. If the sizes are inconsistent, it may cause leakage or poor airflow, which will affect the working performance of the equipment. At the same time, the pressure levels of the air pipe and accessories should match. If the pressure level of the air pipe is low and the pressure level of the accessories is high, the safety of the entire system will be threatened. When selecting air pipes and accessories, be sure to match the size and pressure level of the two to ensure stable operation of the system.

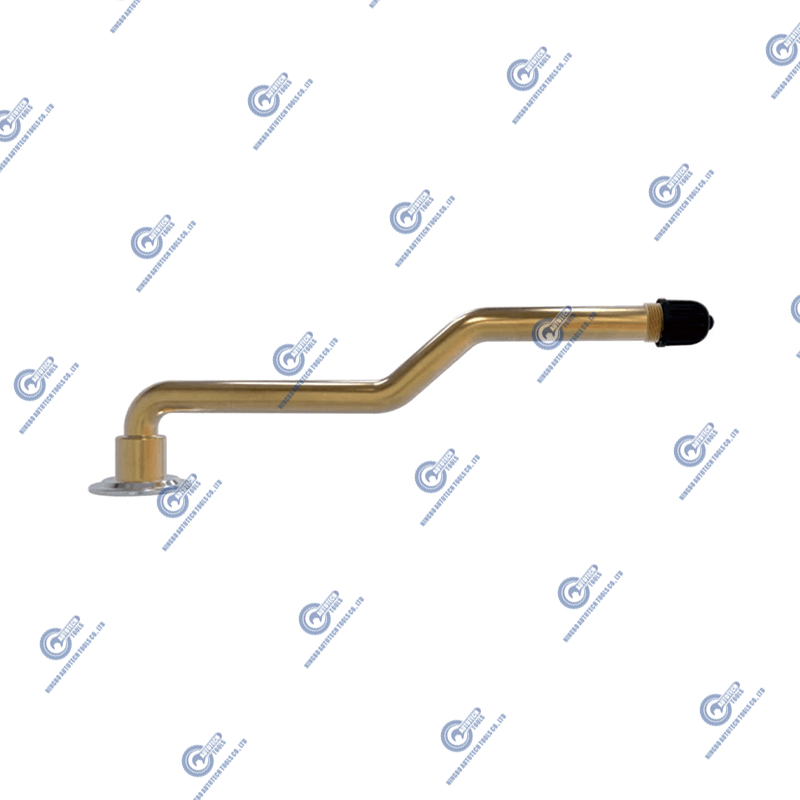

In addition to the size and pressure level, the material selection of air pipes and accessories cannot be ignored. Different materials have different corrosion resistance, wear resistance and high temperature resistance. For example, brass accessories are suitable for anti-corrosion environments, while stainless steel has stronger high temperature and corrosion resistance. When selecting air pipes and accessories, choose the right material according to the specific application scenario to ensure its long-term stability in a specific environment.