Tire Valve Core Selection: Rubber Seals vs. Metal Seals, Which is Better for Extreme Weather?

2025.10.13

2025.10.13

Industry news

Industry news

Tire valves, though small components in a vehicle, play a critical role in ensuring tire safety, preventing leakage, and maintaining proper tire pressure. The material of the valve core significantly impacts its performance under extreme weather conditions, which can greatly affect vehicle safety. Rubber seals and metal seals are two common materials used for valve cores, each offering unique advantages and ideal use cases.

1. Characteristics of Rubber Seal Valve Cores

Rubber valve cores are typically made of rubber sealing rings and other synthetic materials. Due to their lower cost and simpler manufacturing process, rubber valve cores are widely used in standard cars, light trucks, and budget-friendly vehicles.

1.1 Flexibility and Adaptability

One of the primary advantages of rubber seal valve cores is their excellent adaptability and flexibility. The rubber sealing ring can compensate for small gaps between the valve and tire hole, providing stable air tightness. This makes rubber valve cores perform well under normal driving conditions, effectively preventing air leakage.

1.2 Cost and Maintenance

Rubber valve cores are relatively inexpensive and easy to replace, which makes them the most common type on the market. However, they require regular inspection and maintenance, especially in extreme temperature environments, as they can degrade, harden, or crack under such conditions.

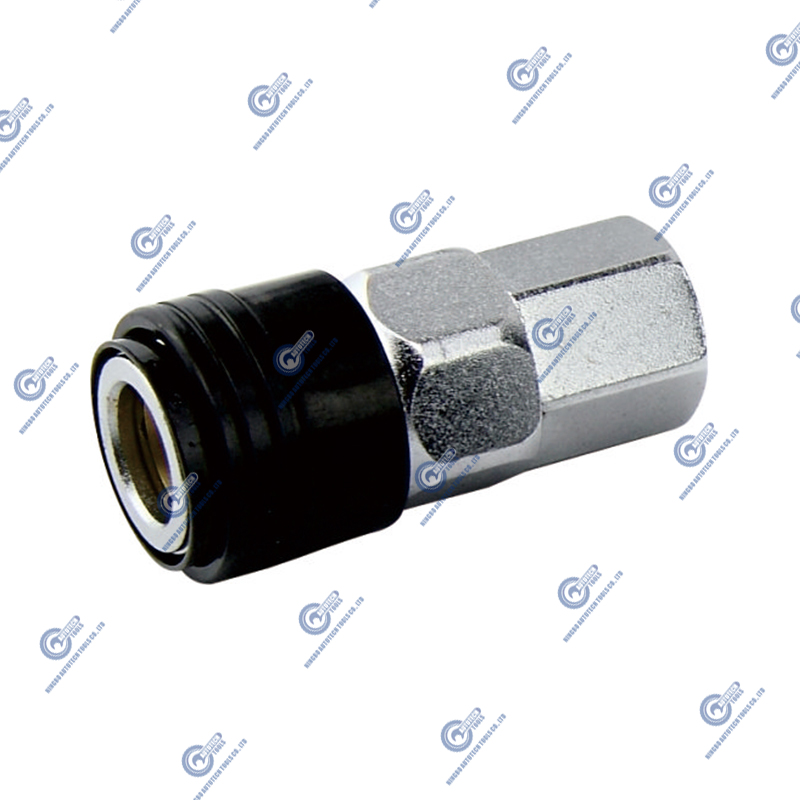

2. Characteristics of Metal Seal Valve Cores

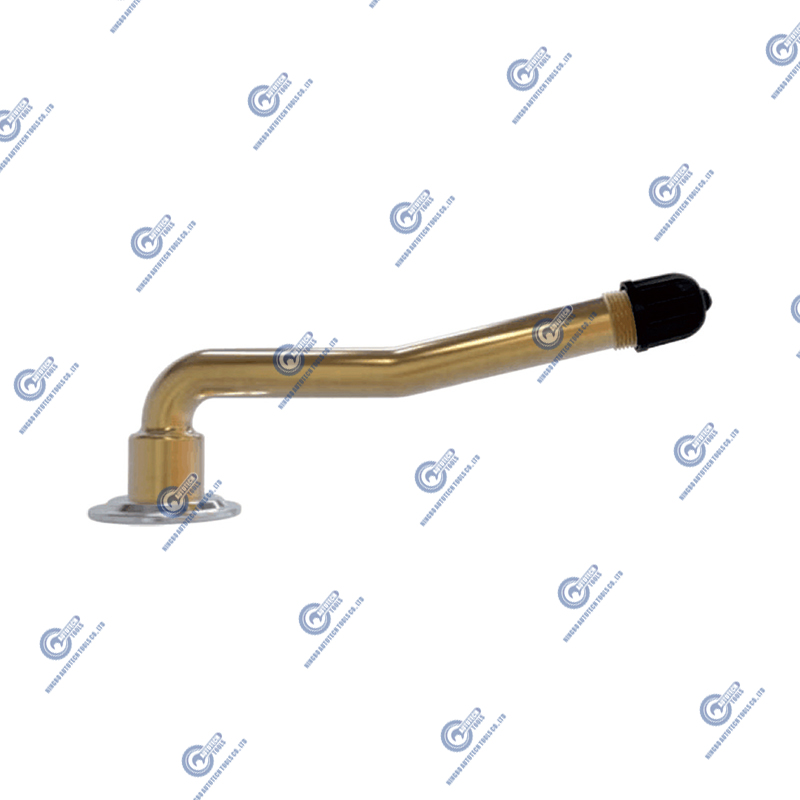

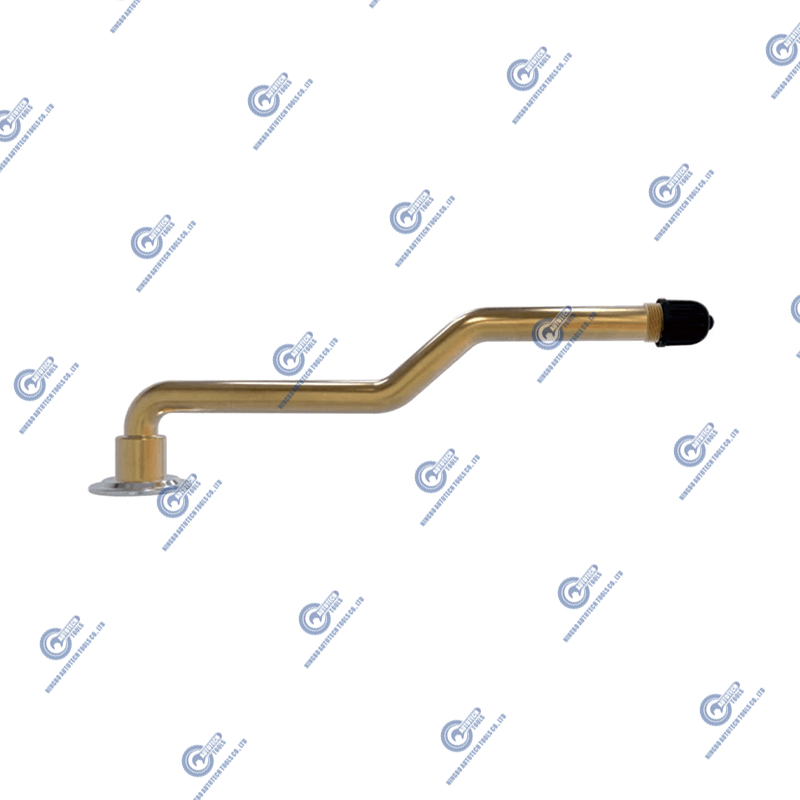

Metal seal valve cores are usually made of metals such as stainless steel or aluminum alloys, offering higher strength and durability. Compared to rubber seals, metal valve cores are more commonly used in high-performance vehicles and extreme conditions.

2.1 High-Temperature Resistance and Strength

A standout feature of metal valve cores is their high-temperature resistance. Unlike rubber materials, metal valve cores do not soften or degrade in high heat, making them capable of handling more demanding operating environments. In racing cars or vehicles subjected to prolonged high-temperature driving, metal valve cores are generally more reliable.

2.2 Suitable for Extreme Weather

The high strength of metal valve cores enables them to better withstand physical impacts from the external environment. This makes metal valve cores more durable in harsh climates, particularly in cold or hot conditions.

3. Performance Comparison in Extreme Weather Conditions

3.1 Performance in Cold Environments

Cold environments cause rubber materials to harden, reducing their flexibility and sealing effectiveness. When temperatures drop below freezing, rubber valve cores become brittle and are more likely to experience air leakage or damage. On the other hand, metal valve cores are less affected by low temperatures and can maintain their strength and stable sealing performance even in extremely cold regions.

Table: Performance of Different Valve Core Materials in Cold Environments

| Valve Type | Low-Temperature Adaptability | Sealing Stability | Failure Risk |

|---|---|---|---|

| Rubber Valve | Poor | Decreases easily | High |

| Metal Valve | Good | Stable | Low |

3.2 Performance in High-Temperature Environments

In high-temperature environments, rubber valve cores are prone to aging, softening, and expanding, which leads to a decrease in sealing efficiency and affects tire pressure stability. Metal valve cores, however, perform more robustly under high heat, as their metal structure can endure prolonged exposure to elevated temperatures without deforming or failing. For vehicles in hot climates or those frequently subjected to high temperatures, metal valve cores are clearly the better choice.

3.3 Performance in Wet and Corrosive Environments

In wet or rainy environments, rubber valve cores are more likely to experience reduced sealing performance. Prolonged exposure to moisture can lead to corrosion and aging of the rubber material, further compromising its air tightness. By contrast, metal valve cores, especially those made from stainless steel or aluminum alloys, exhibit much better corrosion resistance, making them more suitable for humid or marine climates.

4. Analysis of Suitable Scenarios

4.1 Cold Climate Areas

In cold climates, temperatures often drop below freezing, and rubber valve cores’ performance can be significantly impacted. To avoid issues with decreased sealing and potential damage to the valve from low temperatures, car owners in these regions should consider using metal valve cores, especially those made of low-temperature-resistant metals like stainless steel.

4.2 Hot Climates and Desert Areas

High-temperature environments place extreme demands on a vehicle’s components. Rubber valve cores in such climates may degrade and fail due to the high temperatures. Metal valve cores, with their superior heat resistance, are much better suited for these conditions, as they can maintain reliable performance even under prolonged exposure to heat. For vehicles in desert regions or high-temperature environments, metal valve cores are undoubtedly the more reliable option.

4.3 Mixed Climate and Urban Commuting

For most urban commuters, the climate is not as extreme as those in harsh cold or hot environments. Rubber valve cores are generally sufficient for daily driving in moderate climates, offering a good balance of cost and performance. While metal valve cores provide greater durability, their higher cost and more complex installation process may not be necessary for most drivers.