Snap-in Tubeless Tire Valves vs. Clamp-in Valves: Which is Better for Your Tire?

2025.10.06

2025.10.06

Industry news

Industry news

Introduction

In modern car and motorcycle tire systems, tire valves play a crucial role. They not only maintain proper tire pressure but also directly affect driving safety, fuel efficiency, and tire lifespan. With the increasing popularity of tubeless tires, two main types of valves have become widely used: Snap-in Tubeless Tire Valves and Clamp-in Valves.

Many vehicle owners and service professionals often wonder: what are the differences between these two types of valves? Which one is more suitable for my vehicle?

Snap-in Tubeless Tire Valves Overview

Working Principle

Snap-in Tubeless Tire Valves are mainly made of rubber and rely on the rubber flange at the base of the valve to fit tightly into the wheel rim hole. During installation, the valve is simply pushed or pressed into the rim using a hand tool or by hand, without requiring nuts or washers.

This design allows Snap-in valves to offer quick installation and easy replacement while maintaining airtightness. The rubber material also provides slight flexibility, helping absorb minor impacts and preventing air leakage during regular driving.

Key Features

- Easy installation: Can be installed in seconds without complicated tools.

- Low cost: Rubber construction is inexpensive to produce and purchase.

- High adaptability: Suitable for various passenger car and light vehicle tire sizes.

- Good flexibility: Rubber can maintain a seal under minor impacts or vibrations.

Common Applications

- Daily passenger car tires

- Motorcycle tires

- Light truck tires

- Small low-speed vehicles

Advantages & Limitations

Advantages: Quick installation, low cost, suitable for everyday driving.

Limitations: Not suitable for high-pressure tires; rubber can age over time, resulting in a shorter lifespan.

Clamp-in Valves Overview

Working Principle

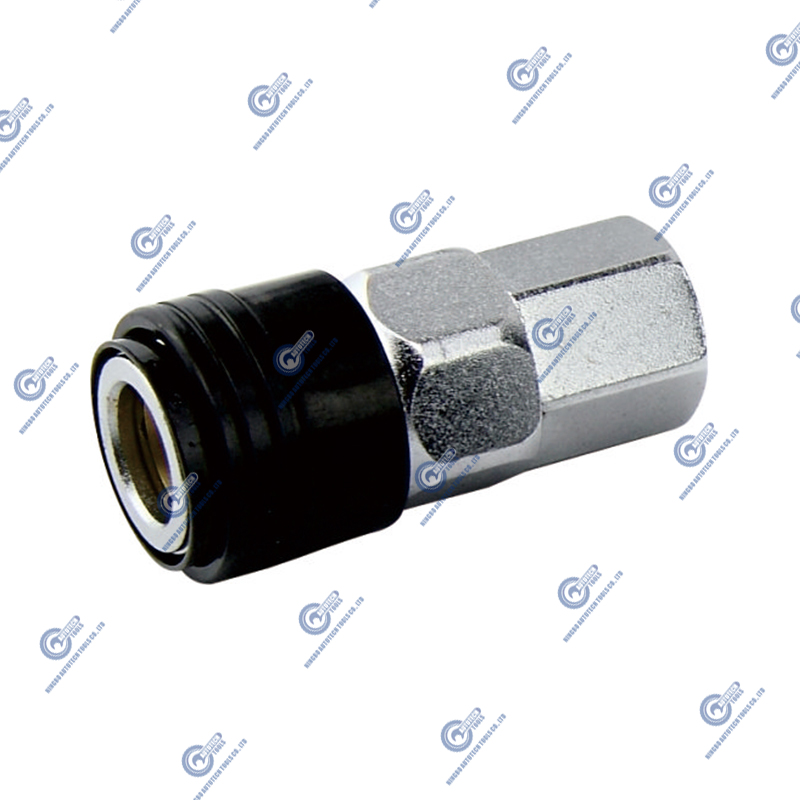

Clamp-in Valves are typically made of metal, such as brass or aluminum, and are secured to the wheel rim using a nut and washer. During installation, the valve is inserted into the rim hole, and the nut is tightened to ensure a firm and secure fit.

Due to the metal construction and mechanical fastening, Clamp-in Valves provide higher pressure tolerance and greater durability, making them suitable for high-performance vehicles or tires requiring higher air pressure.

Key Features

- High pressure tolerance: Can withstand higher tire pressures, suitable for trucks, SUVs, and performance cars.

- Heat resistance: Metal construction resists heat generated from braking systems.

- Durable: Metal is less prone to wear and corrosion, ensuring a longer lifespan.

- Aesthetic appeal: Metal valves offer a premium look for high-end or modified vehicles.

Common Applications

- High-performance car tires

- Truck and SUV tires

- High-speed vehicles

- Modified cars and racing vehicles

Advantages & Limitations

Advantages: Stronger pressure resistance, durable, suitable for high-temperature and high-pressure conditions.

Limitations: Installation is more complex, and the cost is higher than Snap-in valves.

Snap-in vs Clamp-in Valves: Key Comparisons

Pressure Tolerance

- Snap-in Valves: Typically suitable for low to medium tire pressure, up to approximately 65 PSI.

- Clamp-in Valves: Designed for high-pressure tires, exceeding 65 PSI, suitable for high-speed or heavy-load conditions.

Durability

- Snap-in Valves: Rubber material may degrade over time, limiting lifespan.

- Clamp-in Valves: Metal construction resists wear and heat, offering a longer lifespan for long-term use.

Installation

- Snap-in Valves: Quick installation without nuts, ideal for bulk tire replacement.

- Clamp-in Valves: Requires nut tightening, slightly more complex, but provides a secure fit.

Cost

- Snap-in Valves: Affordable, suitable for everyday passenger car users.

- Clamp-in Valves: Higher price, but offers long-term reliability and durability.

Aesthetics

- Snap-in Valves: Simple appearance, function-focused.

- Clamp-in Valves: Metallic finish is more attractive, ideal for high-end or modified vehicles.

Comparison Table

| Feature | Snap-in Tubeless Tire Valves | Clamp-in Valves |

|---|---|---|

| Pressure Tolerance | ≤ 65 PSI | ≥ 65 PSI |

| Material | Rubber | Metal (brass/aluminum) |

| Durability | Moderate, prone to aging | Long-lasting, heat-resistant |

| Installation | Quick and easy | Requires nut tightening |

| Cost | Low | Higher |

| Typical Use | Passenger cars, motorcycles | Trucks, SUVs, high-performance cars |

Which One Should You Choose?

Choose Snap-in Tubeless Tire Valves If:

- Your vehicle is a regular passenger car or motorcycle

- Daily driving tire pressures are relatively low

- You prioritize ease of installation and cost savings

- Tire usage environment has mild temperature and pressure conditions

Choose Clamp-in Valves If:

- Your vehicle is a truck, SUV, or high-performance car

- Tires require high pressure or heat resistance

- You value long-term durability and safety

- Driving conditions are demanding (high speed, heavy load, long distances)