Comparison between Clamp-in Tire Valves and Traditional Valve Cores: Safer and More Efficient

2025.09.15

2025.09.15

Industry news

Industry news

Introduction: How Valve Core Selection Affects Safety and Efficiency

In modern vehicles, tires are the most direct point of contact with the road, and their safety and performance directly impact the vehicle’s driving effects and the driver’s safety. As a crucial component of tires, the tire valve core plays an important role in maintaining tire pressure and preventing air leaks. While traditional valve cores have been in use for many years across various vehicle types, with technological advancements, Clamp-in Tire Valves (clamp-style valve cores) have gradually entered the market and gained favor. They not only improve tire sealing but also provide better resistance to high pressure and high temperatures.

1. What Are Clamp-in Tire Valves?

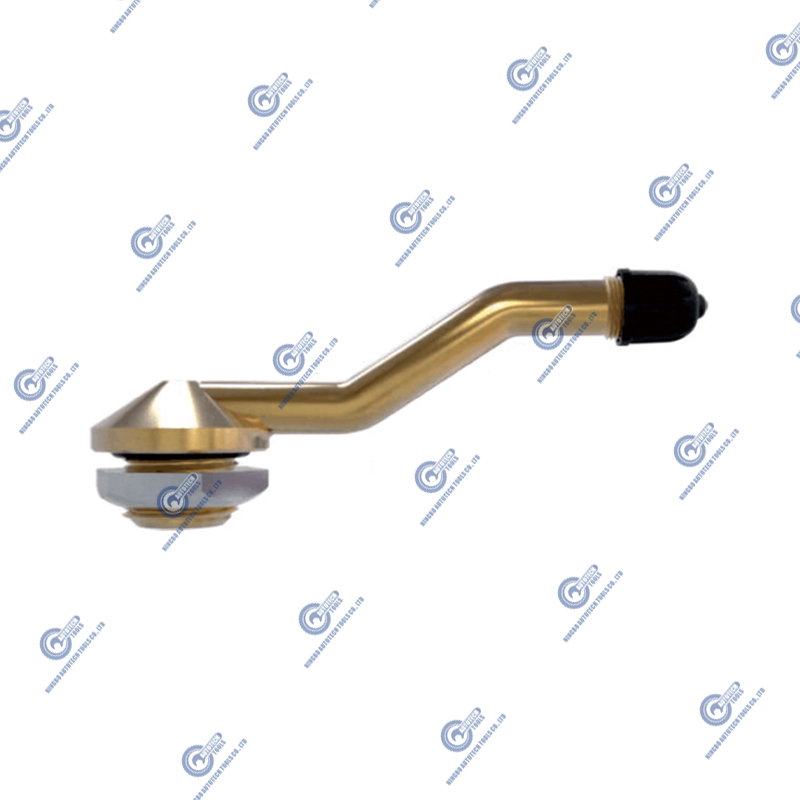

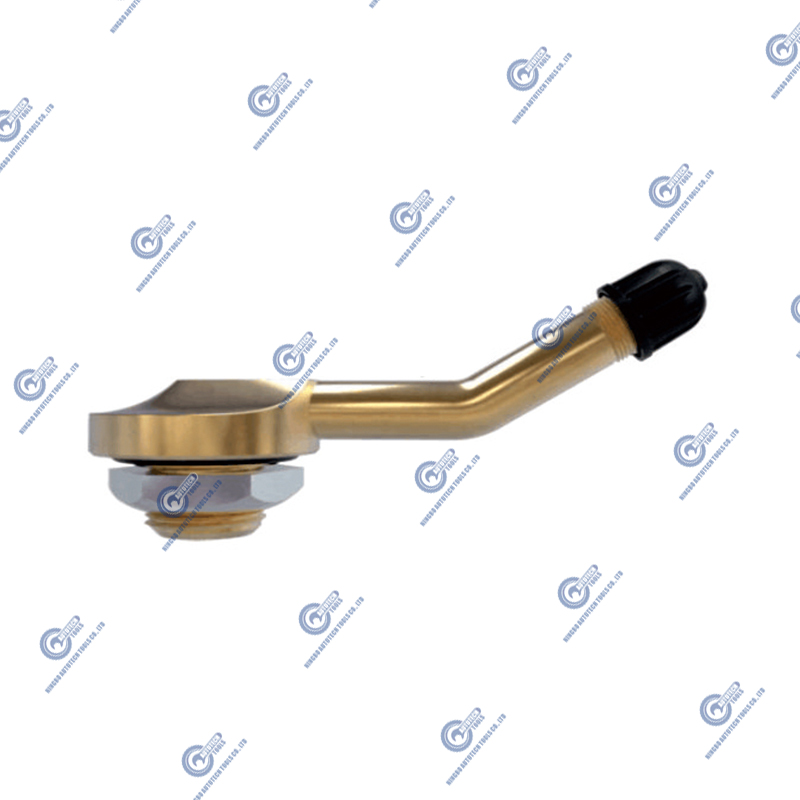

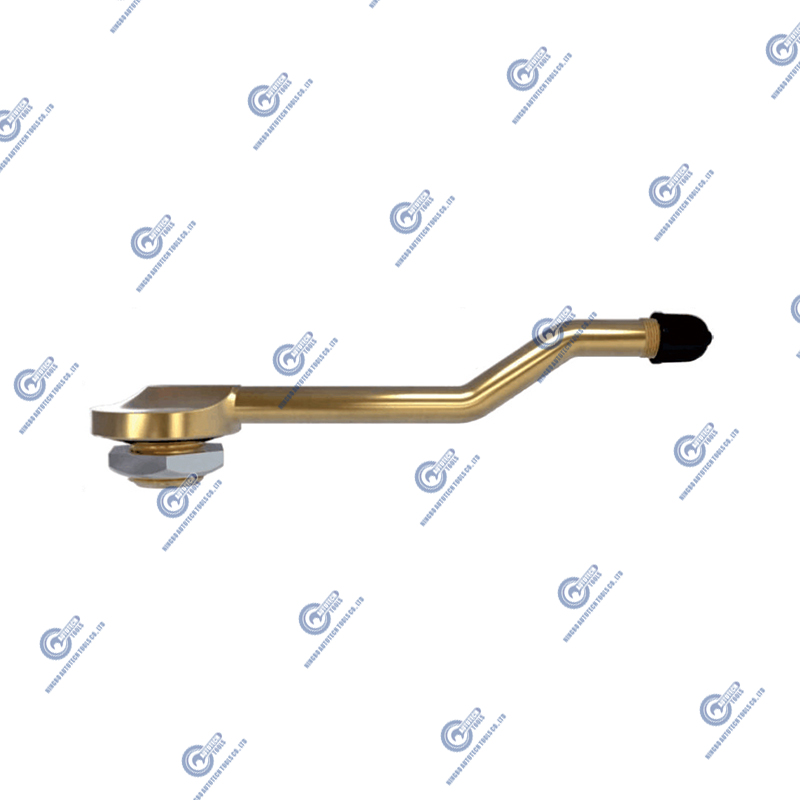

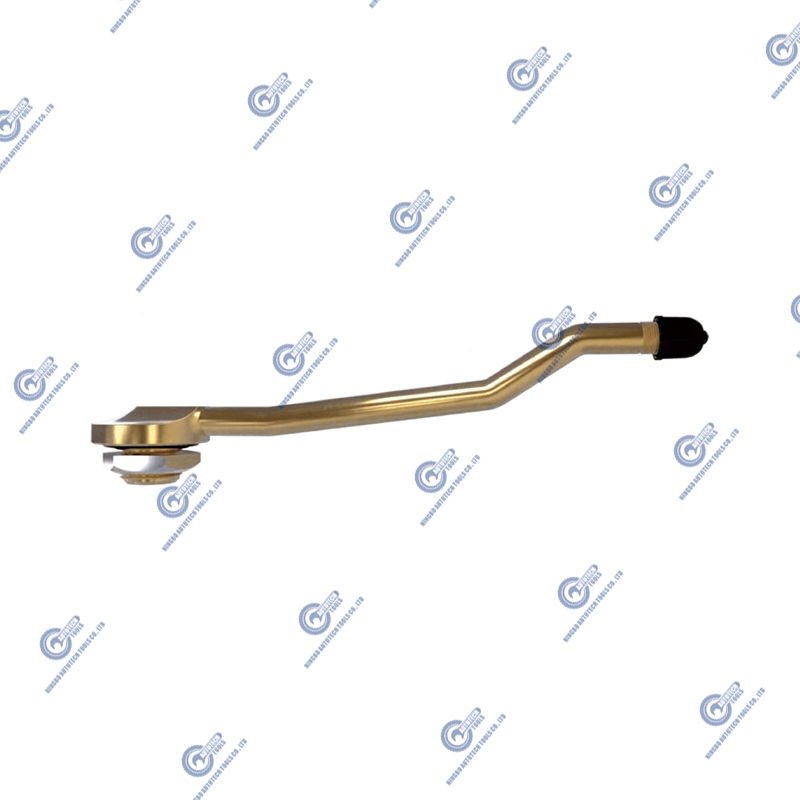

Definition and Features of Clamp-in Tire Valves

As the name suggests, Clamp-in Tire Valves are valve cores that are fixed to the wheel rim using a clamp. Unlike traditional valve cores that rely on rubber seals to fit tightly with the rim, Clamp-in Tire Valves use a metal clamp to securely attach the valve to the rim, providing superior sealing.

These valve cores are widely used in high-performance tires and heavy-duty vehicles, especially in commercial trucks and sports cars, where they effectively reduce the risk of air leakage and improve tire safety and durability.

How They Work:

The structure of Clamp-in Tire Valves includes a metal clamp and an internal valve. The metal clamp tightly secures the valve to the rim, forming a reliable seal with the tire’s air chamber. The internal valve maintains tire pressure stability during operation. This clamp design allows Clamp-in Tire Valves to better withstand high-pressure, high-temperature, and vibration environments compared to traditional valve cores.

2. How Traditional Valve Cores Work

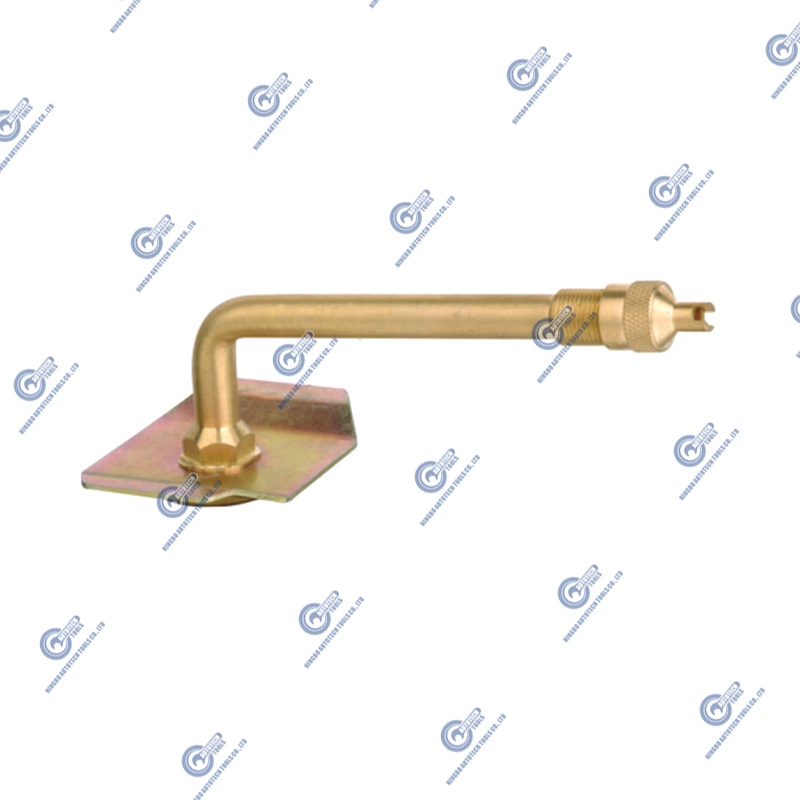

Structure and Function of Traditional Valve Cores

Traditional valve cores use a rubber seal that fits against the wheel rim to prevent air from leaking out of the tire. The valve core is inserted into the wheel rim’s valve hole, and the rubber seal is used to ensure an airtight seal between the tire and the rim.

Traditional valve cores are commonly used in passenger cars, light trucks, and everyday vehicles. While this design is simple and cost-effective, it can become problematic when dealing with high-pressure or high-temperature conditions.

Installation and Use:

The installation of traditional valve cores is relatively simple. The valve core is inserted into the rim’s valve hole and tightened by hand or with a tool. However, if the installation is not done correctly, the rubber seal may fail to seal properly, resulting in air leaks. Over time, the rubber seal can degrade, crack, or lose its elasticity, further compromising the sealing performance.

3. Advantages of Clamp-in Tire Valves

Superior Sealing Performance

One of the key advantages of Clamp-in Tire Valves over traditional valve cores is their superior sealing performance. The clamp design creates a stronger, more stable seal with the rim, making it much harder for air to leak. This is particularly important in high-pressure tire applications, where traditional valve cores often fail to provide an effective seal. With Clamp-in Tire Valves, you can rely on better tire pressure stability, reducing safety risks caused by air loss.

Resistance to High Pressure and High Temperature

Some high-performance and heavy-duty vehicles require tires that can withstand higher pressures and temperatures. Traditional valve cores often cannot handle these demanding conditions. Clamp-in Tire Valves, on the other hand, are designed with a metal clamp that can effectively resist high pressure and high temperatures, ensuring better stability and longer service life for the valve and tire. By using Clamp-in Tire Valves, the lifespan of the tire can be extended while maintaining its performance.

Vibration Resistance and Durability

Clamp-in Tire Valves also have better vibration resistance. Tires undergo significant vibrations and shocks, especially on rough or uneven roads. The metal clamp design of Clamp-in Tire Valves helps to reduce the impact of these vibrations, maintaining tire pressure stability and preventing air leaks caused by shock or vibration. This makes them more durable in the long run.

4. Disadvantages of Traditional Valve Cores

Susceptibility to Wear and Aging

Traditional valve cores are made of rubber, which is prone to aging, cracking, or becoming brittle due to exposure to high temperatures, UV rays, and oxidation. Once the rubber seal loses its elasticity, the sealing performance of the valve core is compromised, leading to air leakage. This issue is often more noticeable in high-temperature conditions or after long-term use.

Installation Complexity

Although traditional valve cores are relatively easy to install, improper installation under high-pressure conditions can lead to loose cores or poor seals, resulting in air leakage. Correct installation requires experience and expertise to ensure that the valve core is installed properly.

Limited Suitability for High-Pressure Tires

For high-performance or commercial vehicles, tires often require higher pressure, which traditional valve cores are not always designed to handle. High-pressure environments can cause traditional valve cores to wear out faster, resulting in diminished sealing performance and a higher risk of failure.

5. Applications of Clamp-in Tire Valves

High-Performance Vehicles

Clamp-in Tire Valves are particularly suited for high-performance vehicles such as sports cars and race cars. These vehicles often require higher tire pressures to improve traction and handling. Clamp-in Tire Valves can maintain a stable seal under high-pressure conditions, which is essential for vehicle safety and performance.

Heavy-Duty Trucks and Commercial Vehicles

In heavy-duty trucks and long-distance commercial vehicles, tires are subjected to prolonged high-speed travel and heavy loads. Traditional valve cores may fail under these conditions, while Clamp-in Tire Valves offer superior support and durability. These valve cores are more suitable for vehicles that operate in extreme conditions and require higher air pressure.

Specialty Vehicles

For vehicles like off-road cars, tractors, and other special-purpose vehicles, which often operate in harsh terrains or extreme climates, traditional valve cores may not provide the required performance. Clamp-in Tire Valves, with their stronger vibration resistance and high-pressure capability, offer better protection and durability in such extreme environments.

6. How to Choose the Right Valve Core

Consider the Vehicle Type and Usage Requirements

When selecting a valve core, the most important factors to consider are the vehicle type and the conditions in which it will be used. For vehicles that frequently travel on highways or rough roads, and require higher tire pressure, Clamp-in Tire Valves are a better choice. For everyday use in regular passenger cars, traditional valve cores may suffice.

Material and Durability of Valve Cores

It is also essential to consider the material and durability of the valve core. Traditional valve cores are typically made of rubber or plastic, while Clamp-in Tire Valves are made of metal, which provides better resistance to heat, corrosion, and wear. Choosing the right material ensures the longevity of the valve and reduces maintenance needs.

7. Why Choose Clamp-in Tire Valves?

Clamp-in Tire Valves, compared to traditional valve cores, offer superior sealing, resistance to high pressures and temperatures, vibration resistance, and durability. For vehicles that require high performance or are used in extreme conditions, opting for Clamp-in Tire Valves improves tire safety and stability, extending the life of the tire and reducing maintenance costs. While traditional valve cores may still suffice for everyday vehicles, Clamp-in Tire Valves are undoubtedly the preferred choice for high-performance, heavy-duty, and specialty vehicles.

| Feature | Clamp-in Tire Valves | Traditional Valve Cores |

|---|---|---|

| Sealing Performance | Stronger (metal clamp design) | Weaker (rubber seal) |

| High Pressure Resistance | Excellent (suitable for high-pressure tires) | Poor (prone to wear) |

| High Temperature Resistance | Strong (designed for high temperatures) | Weaker (prone to aging) |

| Vibration Resistance | Strong (withstands rough environments) | Weaker (vibration may affect seal) |

| Durability | Strong (long-lasting) | Weaker (wears out faster) |