The Essential Guide to Choosing the Right Quick Connect Couplings for Your Needs

2025.09.08

2025.09.08

Industry news

Industry news

What Are Quick Connect Couplings?

Quick connect couplings (QCCs) are mechanical devices that allow users to quickly connect or disconnect fluid or gas lines without the need for tools or special equipment. These couplings are used in a wide variety of industries, including manufacturing, automotive, and chemical processing, to provide a safe, reliable, and efficient way to transfer fluids or gases.

These couplings come in various designs, materials, and configurations, allowing them to be used across a broad range of applications, including pneumatic, hydraulic, vacuum, and chemical systems.

Types of Quick Connect Couplings

Pneumatic Couplings

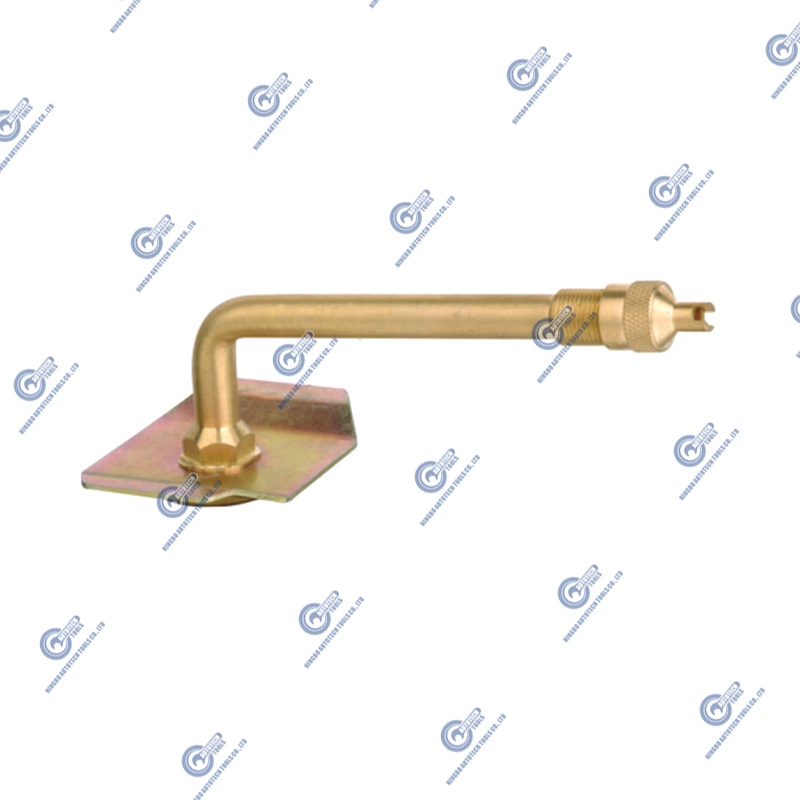

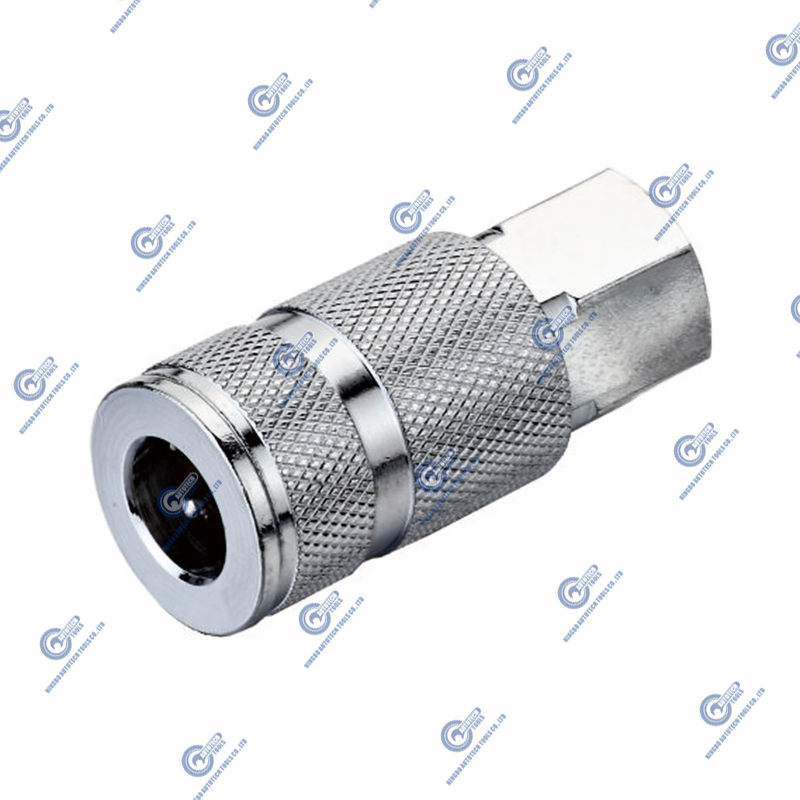

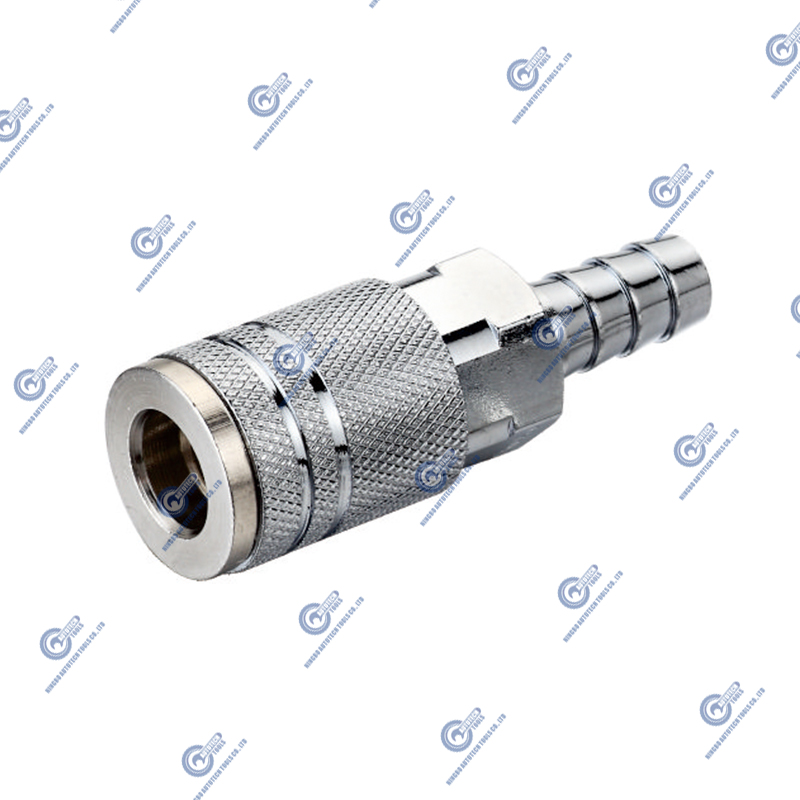

Pneumatic couplings are used in air-powered systems, such as pneumatic tools, compressors, and automated machinery. These couplings are designed to handle the pressures typically found in air systems and can quickly connect or disconnect without leakage. They often feature push-to-connect mechanisms and come in a variety of sizes and flow ratings.

Hydraulic Couplings

Hydraulic couplings are designed for high-pressure fluid transfer applications. They are commonly found in construction, mining, and agricultural equipment, where they are used to connect hydraulic hoses that carry fluids under pressure. These couplings are robust and must be designed to withstand the stress and pressure associated with hydraulic systems.

Chemical Couplings

Chemical couplings are specifically designed to handle the safe transfer of chemicals, including those that are corrosive or hazardous. These couplings are made from special materials such as stainless steel, polypropylene, or other corrosion-resistant alloys. They often feature specialized seals to prevent leaks and contamination.

Vacuum Couplings

Vacuum couplings are designed for applications that require the transfer of gases in a vacuum environment. These couplings are commonly used in laboratory settings, semiconductor manufacturing, and specialized medical equipment. Their design ensures that they do not leak air when connecting or disconnecting in low-pressure environments.

Factors to Consider When Choosing Quick Connect Couplings

Pressure Rating

One of the most important considerations when selecting quick connect couplings is the pressure rating. Each coupling is designed to withstand a certain maximum pressure, and exceeding this pressure can result in coupling failure. It’s crucial to match the pressure rating of the coupling with the working pressure of your system to ensure safety and reliability.

Material Compatibility

Different materials react differently when exposed to various fluids and gases. Stainless steel, brass, aluminum, and polymer-based materials each have unique properties that make them more or less suited for certain environments. For instance:

- Stainless steel is resistant to corrosion and can handle harsh chemicals.

- Brass is ideal for water systems but may corrode in highly acidic or basic environments.

- Polymer-based couplings are lightweight and resistant to certain chemicals but may not be suitable for high-pressure applications.

Temperature Range

Quick connect couplings are rated for specific temperature ranges. For example, rubber seals may degrade in high temperatures, and certain metals become brittle in extremely cold conditions. Always check the temperature range of the coupling to ensure it is suitable for the operating conditions.

Size and Flow Rate

Choosing the correct coupling size ensures that the connection can handle the desired flow rate without restrictions. A coupling that is too small for the system will cause reduced flow, pressure drops, and potential damage to both the coupling and the system. A coupling that is too large may be unnecessary and more expensive than needed.

Sealing Mechanism

The sealing mechanism ensures that the coupling does not leak when connected or disconnected. There are several types of seals, including:

- Single-seal couplings: Common for low-pressure applications.

- Double-seal couplings: Used in high-pressure environments where extra safety is required.

- Push-to-connect: A convenient option for frequent connect/disconnect cycles.

Choosing Based on Application

Industrial Use

In industrial settings, where machinery is subject to constant operation, durability is key. Quick connect couplings are typically used in pneumatic systems to connect tools to air compressors, in hydraulic systems for heavy machinery, and in coolant systems. The selection of the right coupling depends on the specific requirements of the machinery and its operating conditions.

Automotive and Manufacturing

In automotive repairs or manufacturing, quick connect couplings are used to quickly connect air hoses, fuel lines, and other fluid transfer systems. The coupling must be able to handle the specific fluid or gas and maintain performance under vibration or pressure changes.

Laboratories and Research

In laboratory environments, precision and cleanliness are paramount. Quick connect couplings used in these settings must prevent contamination and allow for quick, secure connections to sensitive equipment. Materials such as stainless steel or PTFE are often preferred for their resistance to corrosion and easy cleaning.

Environmental and Safety Considerations

Corrosion Resistance

For applications in harsh environments, such as chemical plants or offshore rigs, corrosion resistance is critical. Quick connect couplings made from stainless steel, nickel-plated brass, or other corrosion-resistant materials ensure that the coupling can withstand exposure to moisture, chemicals, and saltwater without degrading.

Locking Mechanisms

Locking mechanisms are vital for preventing accidental disconnections, which could lead to leaks or safety hazards. Ball-lock, pin-lock, or threaded locking mechanisms ensure a secure connection. These are commonly used in high-risk applications where safety is a concern, such as fuel lines or hazardous fluid transfer systems.

Cleanliness and Contamination Prevention

For systems involving sensitive chemicals, food products, or pharmaceuticals, cleanliness is essential. Quick connect couplings with cleaning ports or those designed to be easily cleaned can help prevent cross-contamination between materials. These couplings are also designed to prevent foreign particles from entering the system.

Common Mistakes to Avoid

Overlooking Compatibility

One of the most common mistakes is choosing a coupling without considering the full range of compatibility factors. Using a coupling that does not match the system’s pressure, temperature, or material compatibility can result in leaks, reduced system efficiency, or even catastrophic failure.

Ignoring Durability

Durability is crucial, especially in high-cycle applications. Inexpensive couplings may be tempting, but they often lack the robustness necessary to withstand constant use. Always consider the lifetime cost of the coupling, including maintenance and potential replacements.

Underestimating Maintenance Needs

Even high-quality quick connect couplings require maintenance. Regular inspection of seals, O-rings, and locking mechanisms ensures that the coupling continues to perform as intended.

Maintenance and Longevity Tips

Regular Inspection

Inspect the coupling for signs of wear or damage, including cracks, corrosion, or deterioration of seals. If any damage is noticed, replace the component immediately to prevent system failure.

Cleaning and Lubrication

Some couplings benefit from periodic cleaning to prevent the buildup of dirt or debris. Lubricating moving parts with the appropriate grease or oil can also extend the coupling’s lifespan.

Storage

When not in use, store quick connect couplings in a dry, clean environment to prevent exposure to moisture or corrosive agents.

Comparison of Common Materials for Quick Connect Couplings

| Material | Applications | Pressure Rating | Corrosion Resistance | Cost |

|---|---|---|---|---|

| Stainless Steel | Chemicals, Food, Marine | High | Excellent | High |

| Brass | Water Systems, Mild Chemicals | Medium | Moderate | Medium |

| Polymer | Air, Low Pressure | Low to Medium | Fair | Low |

| Aluminum | General Industrial | Medium | Moderate | Low |