Five Reasons to Choose Clamp-in Tire Valves

2025.07.07

2025.07.07

Industry news

Industry news

The tire valve is a key part of the vehicle tire system. It is responsible for maintaining the stability of the air pressure in the tire and ensuring driving safety. Clamp-in Tire Valves have become the first choice of many car owners and professional technicians due to their structural design and performance advantages.

1. Easy installation, stable and reliable

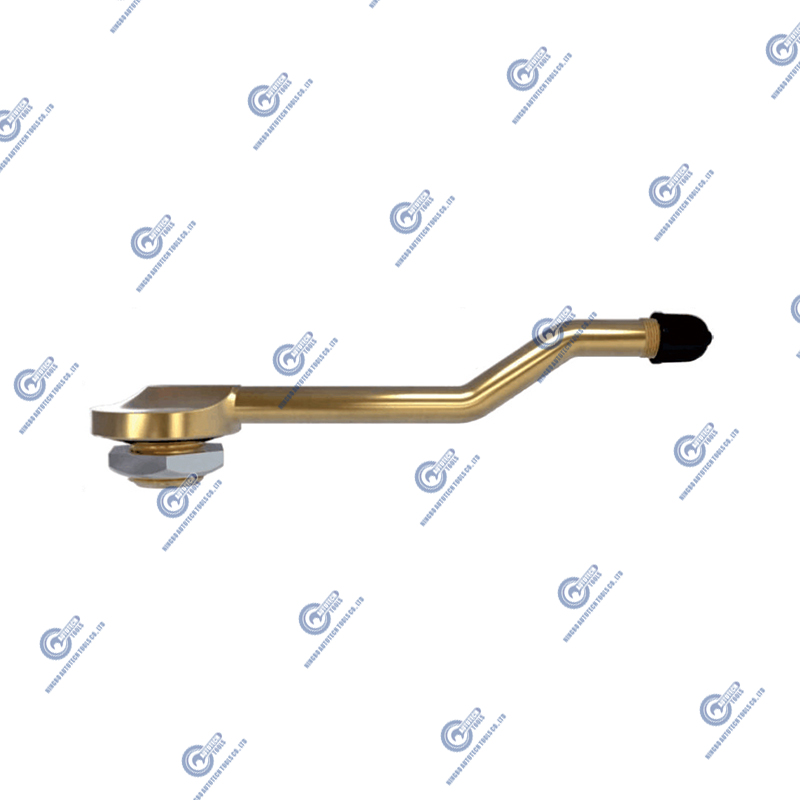

The Clamp-in valve adopts a clamp fixing design, which clamps the valve firmly in the valve hole of the rim. Compared with the traditional threaded valve, the clamp structure does not require complicated installation tools and procedures, which greatly simplifies the installation process. The technician only needs to insert the valve into the rim hole and press the clamp with a special tool to complete the fixation.

The clamp structure effectively prevents the valve from loosening or even falling off due to vibration, temperature changes or pressure fluctuations during driving. This stable installation method not only improves the installation efficiency, but also reduces the risk of air leakage caused by loose valves, ensuring the sealing and overall safety of the tire.

2. Good sealing performance to prevent air leakage

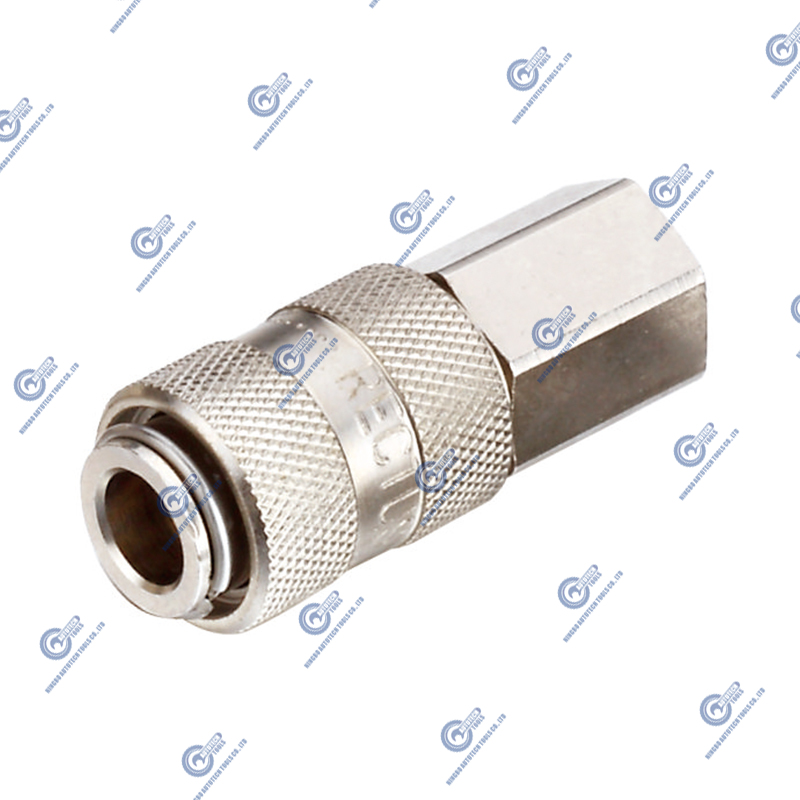

The primary function of the valve is to ensure that the air pressure in the tire does not leak. The Clamp-in valve fits tightly with the rim through a high-quality rubber sealing ring, and the strong clamping of the clamp forms a double sealing barrier. This design greatly reduces the possibility of air leakage.

In actual use, good sealing performance can maintain the stability of tire pressure and avoid the impact of insufficient or excessive tire pressure on tire and vehicle performance. Stable tire pressure not only improves driving comfort, but also reduces tire wear speed, improves fuel economy, and reduces the risk of safety accidents such as tire blowouts.

3. Wide range of applications and compatible with a variety of wheel hub designs

The design of the clamp-in valve takes into full consideration the diverse wheel hub materials and size requirements. Whether it is a common steel wheel hub or a modern aluminum alloy or synthetic material wheel hub, the clamp-type valve can achieve good matching and fixation. This wide compatibility makes it a universal choice for various models and tire maintenance.

Manufacturers usually provide clamp-in valves of different sizes and specifications to meet the needs of different wheel hub apertures and shapes. For vehicle repair shops and car enthusiasts, using this type of universal valve can simplify inventory management and improve maintenance efficiency.

4. Strong durability and excellent corrosion resistance

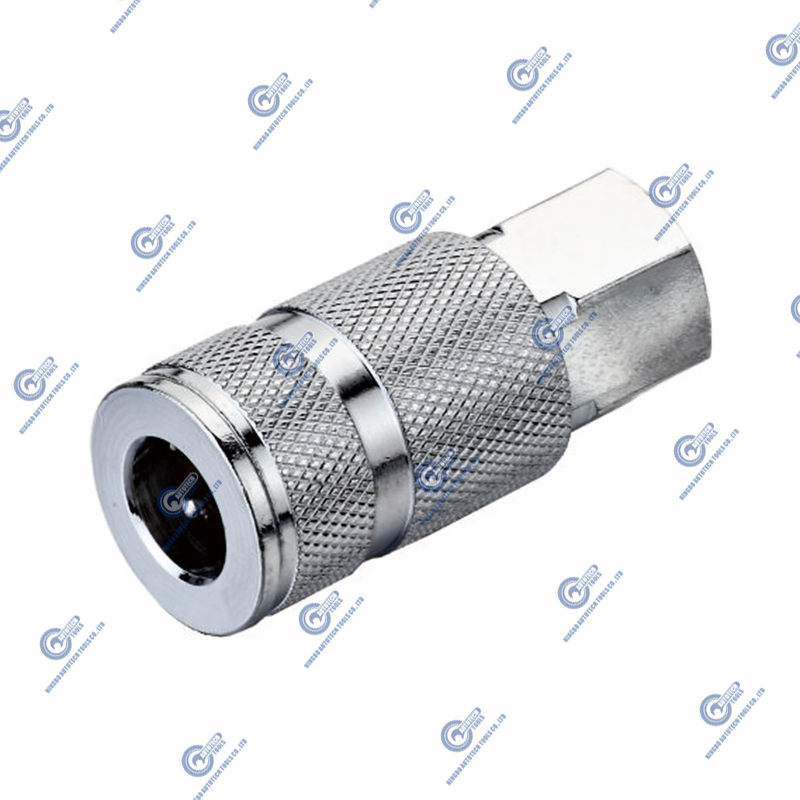

Tire valves are often exposed to harsh outdoor environments, including rain, mud, salt, and road chemicals. Clamp-in valves are usually made of stainless steel or chrome-plated metal clamps combined with high-strength oil-resistant rubber materials, which can effectively resist corrosion, oxidation and mechanical wear.

This durable material combination ensures that the valve can maintain stable performance in high, low and humid environments and extend its service life. Long-term use does not require frequent replacement, which reduces maintenance costs and ensures the long-term safety of vehicle driving.

5. Improve tire safety and reduce accident risks

Tire pressure is crucial to vehicle handling and safety. Abnormal tire pressure may cause tire bursts, extended braking distance or loss of control. The stable sealing and fixing performance of the clamp-in valve effectively ensures the normal operation of the tire pressure monitoring system (TPMS).

Since tire pressure monitoring relies on the valve to accurately transmit pressure information, the clamp-in valve reduces the risk of air pressure leakage and sensor errors, ensuring that the driver can understand the tire status in time and take necessary safety measures. This is especially critical when driving at high speeds and long distances, helping to prevent potential safety accidents.