How Do Quick Connect Air Hose Fittings Improve Work Efficiency?

2025.04.28

2025.04.28

Industry news

Industry news

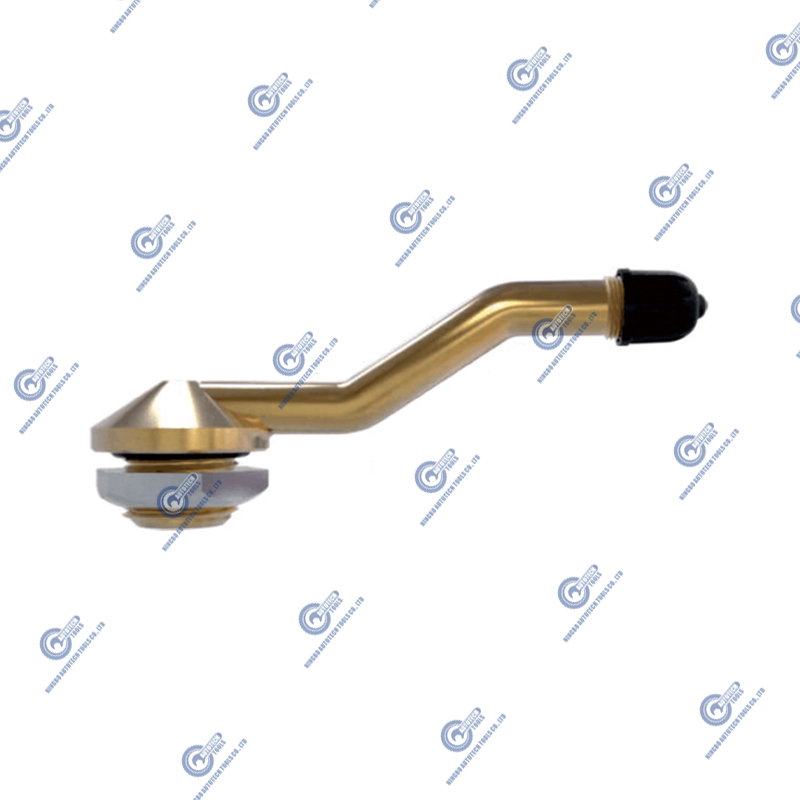

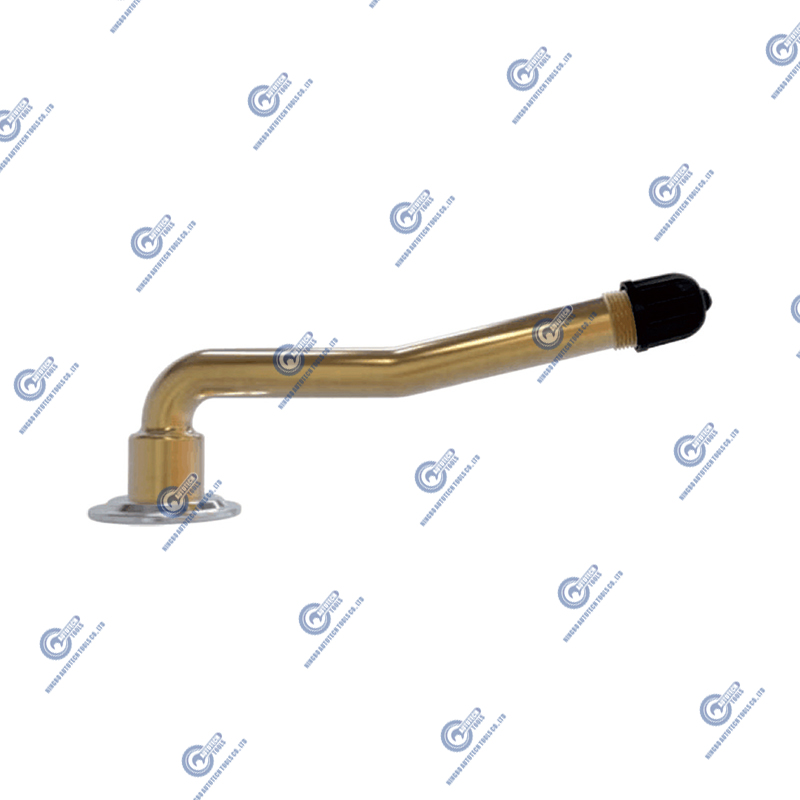

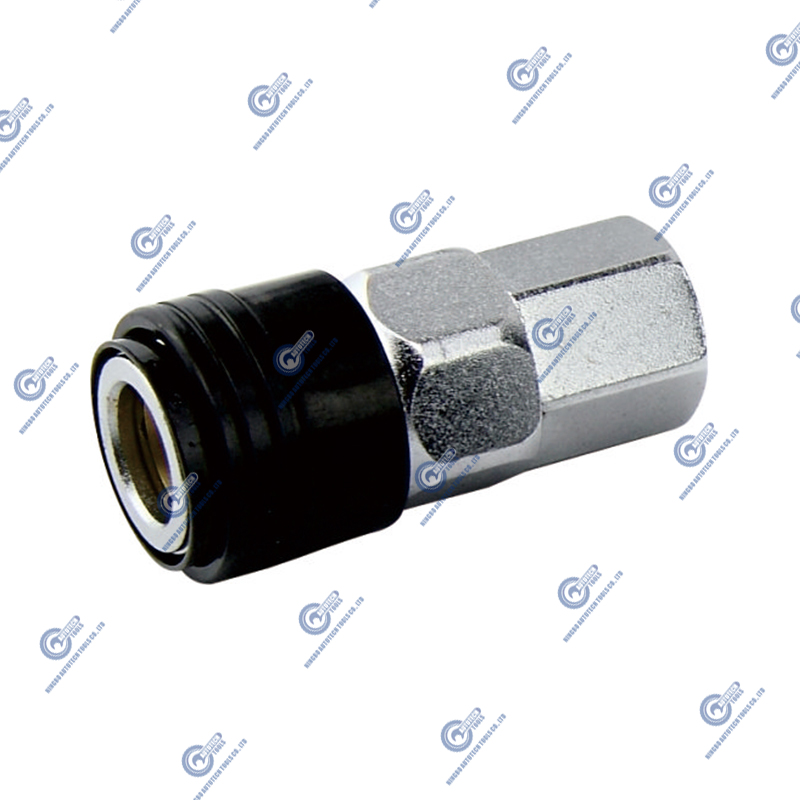

Quick connect air hose fittings are a kind of quick connection device designed to improve the efficiency of pneumatic systems. They adopt a plug-in structure and usually consist of a plug and a socket. When in use, just insert the plug into the socket to complete the automatic locking and sealing without any tool assistance. This design greatly simplifies the connection and disconnection process, allowing workers to install or replace pneumatic tools more quickly in actual operation. In some high-frequency use scenarios, such as auto repair workshops, industrial assembly lines or construction sites, the quick connection feature saves a lot of time, thereby directly improving the overall work efficiency. High-quality quick-connect fittings can effectively reduce air leakage, ensure the stability of system air pressure, and further ensure the continuity and reliability of tool operation.

Compared with traditional threaded fittings, the advantages of quick-connect fittings are particularly obvious. Traditional connection methods usually require tools such as wrenches to tighten and disassemble, which is not only time-consuming and labor-intensive, but also prone to thread damage or slipping due to excessive use. Quick-connect fittings, on the other hand, use precisely designed buckles or spring structures to achieve one-click connection and disconnection, effectively avoiding errors in manual operation. This tool-free operation method not only saves time, but also reduces the labor intensity of workers and equipment failures caused by improper operation. Quick-connect connectors usually have standardized interfaces that are compatible with various types of pneumatic tools, making on-site operations more flexible and convenient. Especially in situations where tools need to be switched frequently, the quick-connect system is undoubtedly the key to improving operation fluency and time utilization.

Quick-connect air hose connectors not only improve efficiency, but also significantly enhance workplace safety. Many quick-connect connectors are designed with an automatic air shut-off function. Once disconnected, the airflow will automatically stop to prevent the air pipe from accidentally popping out or the airflow from suddenly ejecting, avoiding worker injuries or equipment damage. In contrast, traditional connectors are prone to danger if the air source is not completely turned off before disassembly. The structural stability of quick-connect connectors also means that their connections are more secure and not easy to loosen, thereby reducing problems such as insufficient power, abnormal tool operation or production interruptions caused by air leakage. In the long run, this not only improves work efficiency, but also reduces maintenance costs, extends the service life of equipment, and brings higher production stability and benefits to enterprises.