How Do Clamp-In Tire Valves Improve Tire Safety and Performance?

2025.12.15

2025.12.15

Industry news

Industry news

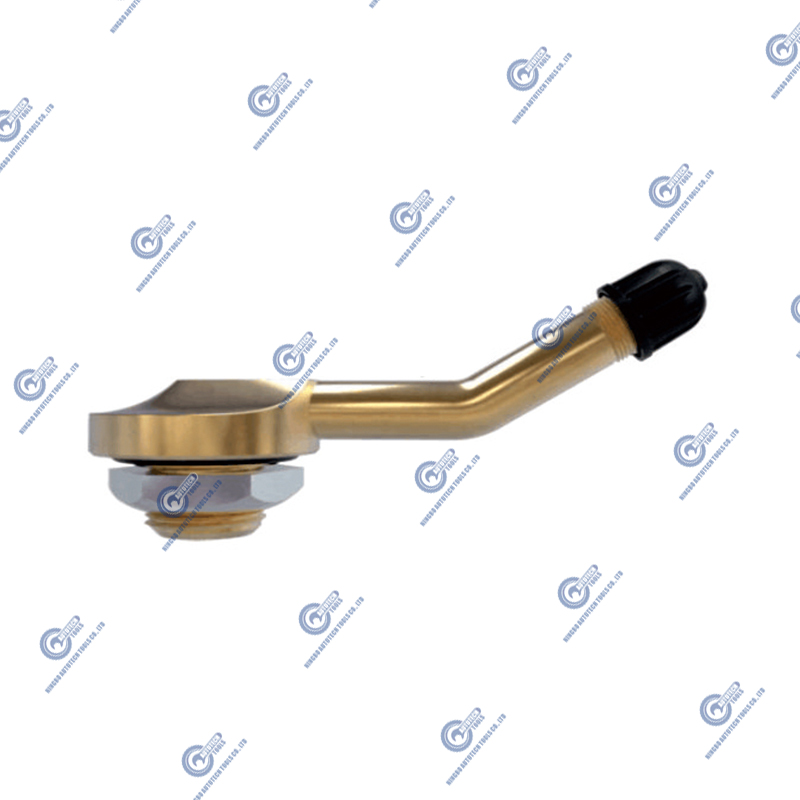

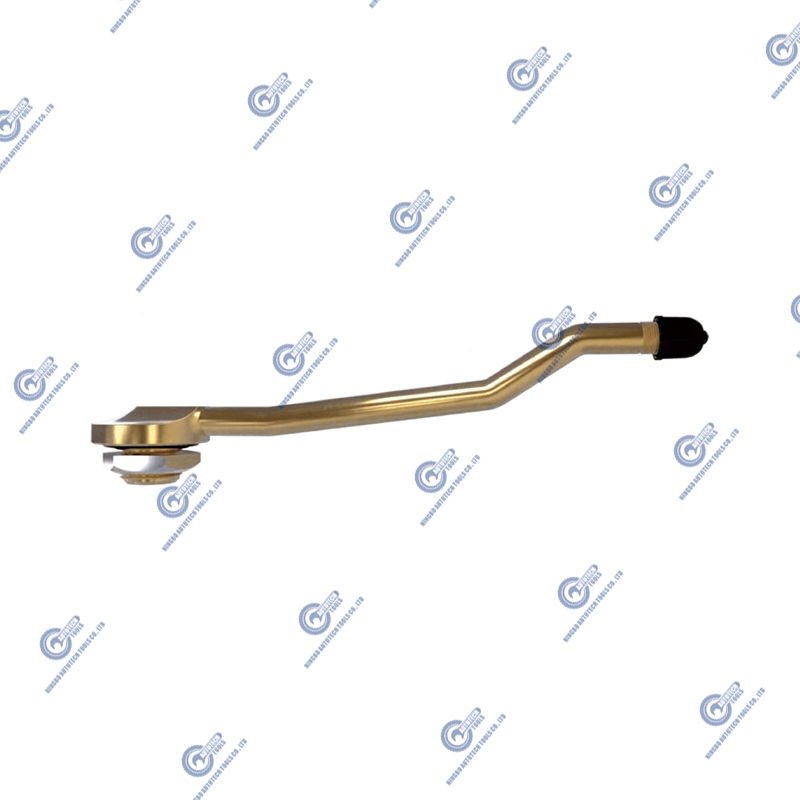

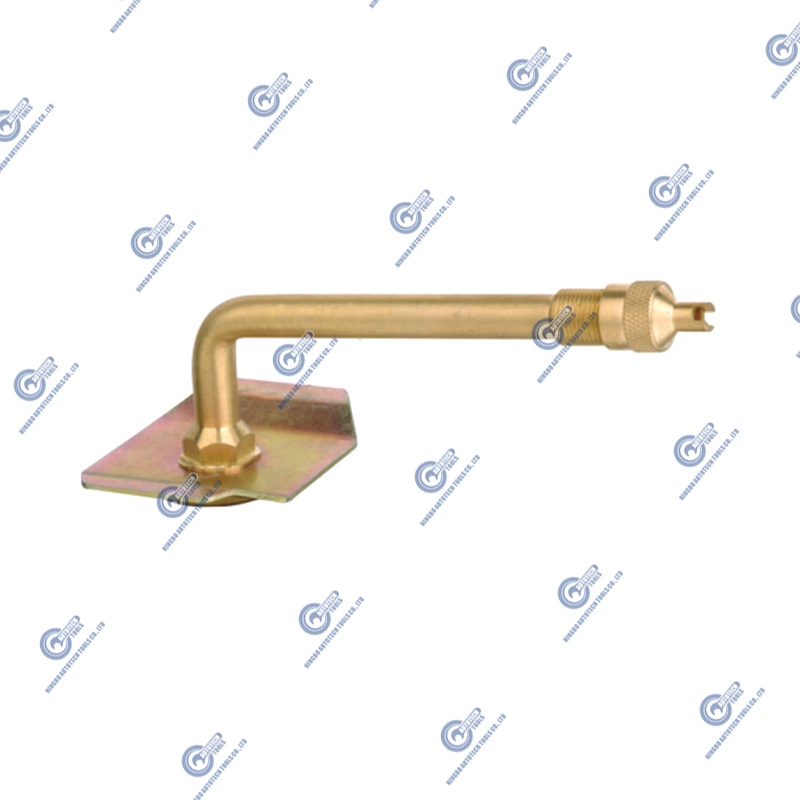

Clamp-in tire valves have become a popular choice for vehicle owners looking to improve tire performance, safety, and longevity. These valves offer a number of benefits over traditional rubber valve stems, making them especially attractive for high-performance, commercial, and everyday vehicles.

1. Better Seal for Air Retention

One of the most significant benefits of clamp-in tire valves is their ability to provide a better seal for air retention. Clamp-in valves are made from durable materials like brass, stainless steel, or aluminum, which ensure a tight seal between the valve and the wheel. This construction helps reduce air leakage, which is a common problem with rubber valves.

-

Impact on Safety: Proper tire inflation is crucial for vehicle safety. Tires that are underinflated or overinflated can cause dangerous driving conditions such as blowouts or poor traction. A strong seal ensures that the tire maintains consistent pressure, reducing the likelihood of tire failure.

-

Impact on Performance: Maintaining the proper tire pressure directly impacts vehicle handling. A well-maintained tire with consistent pressure provides better grip on the road, improved braking performance, and more predictable handling, especially during cornering.

2. Enhanced Durability and Resistance to Wear

Clamp-in tire valves are far more durable than their rubber counterparts. Rubber valves are prone to cracking, drying out, or weakening over time due to exposure to UV rays, ozone, and extreme temperatures. In contrast, clamp-in valves are typically made of corrosion-resistant metals, which can withstand harsh weather conditions and last significantly longer.

-

Impact on Safety: Durability is essential when it comes to tire valves. Over time, rubber valves can degrade and lead to failure, causing sudden air loss or tire deflation. Clamp-in valves, with their robust construction, are less likely to fail, keeping your tire pressures stable and reducing the risk of blowouts.

-

Impact on Performance: The longer lifespan of clamp-in valves means fewer replacements and more consistent tire performance. A valve that remains in good condition for a longer period ensures that the tire maintains proper inflation, which in turn supports smooth driving performance.

3. Improved Tire Balancing

Tire balancing is crucial for vehicle stability and comfort, particularly at high speeds. Clamp-in valves help improve tire balancing because they are securely mounted to the wheel. This solid attachment helps to maintain even pressure distribution within the tire, which reduces vibrations or wobbling that could affect driving.

-

Impact on Safety: An unbalanced tire can lead to uneven wear, reduced handling, and, in extreme cases, a blowout. Clamp-in valves help ensure a more stable, well-balanced tire by preventing air leakage and keeping the tire properly inflated.

-

Impact on Performance: A well-balanced tire offers a smoother ride, reduces wear on suspension components, and improves handling during acceleration, braking, and cornering.

4. Stronger Construction for High-Speed Stability

Vehicles that require high-speed stability, such as sports cars, trucks, and performance vehicles, benefit significantly from clamp-in tire valves. These valves are designed to handle higher air pressures and speeds, reducing the risk of valve failure under stress.

-

Impact on Safety: At high speeds, tires undergo significant pressure, and a weak valve could lead to air leakage, causing a dangerous drop in tire pressure. Clamp-in valves are engineered to withstand these conditions, providing safer driving at higher velocities.

-

Impact on Performance: High-performance vehicles rely on stability at high speeds. Clamp-in valves provide the strength needed to maintain tire pressure, ensuring that the vehicle remains stable and responsive at top speeds.

5. Resistance to Corrosion from Chemicals

Clamp-in tire valves are typically made from corrosion-resistant materials, such as brass, stainless steel, or aluminum, which makes them resistant to corrosion caused by road salt, chemicals, and moisture. This is particularly advantageous for vehicles that drive in areas with harsh winter weather or extreme environmental conditions.

-

Impact on Safety: Corrosion can weaken a valve stem, eventually causing it to fail. By using corrosion-resistant clamp-in valves, the risk of valve failure due to environmental factors is significantly reduced.

-

Impact on Performance: Tires with undamaged valves maintain consistent air pressure, which improves driving performance. Whether it’s through better traction or smoother handling, corrosion-resistant valves ensure that tire pressure is maintained no matter the weather.

6. Prevention of Valve Stem Failure

Valve stem failure is a common issue with traditional rubber valves, especially when the rubber deteriorates due to age or harsh conditions. Clamp-in valves, with their stronger and more durable construction, are less likely to fail.

-

Impact on Safety: A failed valve stem can cause a sudden loss of tire pressure, which can lead to tire blowouts or dangerous driving situations. Clamp-in valves provide extra security against stem failure, making your driving experience safer.

-

Impact on Performance: Consistent air pressure in the tire ensures that your vehicle performs optimally. The tires will last longer, wear evenly, and provide better overall handling, contributing to improved driving dynamics.

7. Compatible with TPMS (Tire Pressure Monitoring System)

Most modern vehicles are equipped with a Tire Pressure Monitoring System (TPMS), which alerts drivers when tire pressure is too low. Clamp-in valves are designed to work seamlessly with TPMS sensors, ensuring accurate readings and early detection of potential issues.

-

Impact on Safety: TPMS plays a crucial role in preventing accidents related to tire pressure. Since clamp-in valves are compatible with TPMS, they help keep tire pressures within safe limits, alerting drivers to any issues before they become hazardous.

-

Impact on Performance: Accurate tire pressure monitoring allows you to maintain the correct pressure, optimizing tire wear and fuel efficiency. This ensures your vehicle performs at its best, reducing the chances of tire-related performance degradation.

8. No Need for Regular Replacements

Clamp-in tire valves have a longer lifespan than rubber valves, meaning they don’t need to be replaced as frequently. This makes them a more convenient and cost-effective option for long-term use.

-

Impact on Safety: Fewer replacements mean less chance of encountering faulty valves unexpectedly, which could lead to tire deflation. With clamp-in valves, you’re assured of greater reliability over time.

-

Impact on Performance: Longer valve lifespans reduce the need for maintenance interruptions, ensuring your tires remain properly inflated and your vehicle performs consistently.

Clamp-In Tire Valves vs. Traditional Rubber Valves

| Feature | Clamp-In Tire Valve | Traditional Rubber Valve |

|---|---|---|

| Material | Brass, Stainless Steel, Aluminum | Rubber |

| Durability | High resistance to wear and corrosion | Prone to cracking and deterioration |

| Air Retention | Excellent seal, low air loss | Moderate seal, potential air loss |

| Installation | Requires professional installation | DIY installation possible |

| Lifespan | Longer lifespan, typically 10-15 years | Shorter lifespan, typically 2-5 years |

| Compatibility with TPMS | Fully compatible | May require additional adapters |

| Cost | Higher upfront cost | Lower upfront cost |

| Environmental Resistance | Highly resistant to chemicals and corrosion | Prone to damage from UV and chemicals |

FAQ: Frequently Asked Questions About Clamp-In Tire Valves

Q1: How often do I need to replace clamp-in tire valves?

Clamp-in tire valves typically last 10-15 years, depending on the vehicle and environmental conditions. Unlike rubber valves, which degrade more quickly, clamp-in valves are built for long-term durability.

Q2: Can I install clamp-in tire valves myself?

While it is possible for experienced DIYers to install clamp-in tire valves, it’s recommended to have them installed by a professional tire technician. This ensures that they are properly clamped and sealed to prevent air leaks.

Q3: Do clamp-in tire valves work with all types of vehicles?

Yes, clamp-in tire valves can be used on most vehicles, including passenger cars, trucks, SUVs, and performance vehicles. However, some high-performance or custom wheels may require specific types of clamp-in valves.

Q4: Will clamp-in tire valves affect my tire pressure monitoring system (TPMS)?

No, clamp-in tire valves are fully compatible with TPMS and can help ensure accurate pressure readings. This makes them an ideal choice for modern vehicles with tire pressure monitoring systems.

Q5: Are clamp-in tire valves worth the extra cost?

Yes, especially for those looking for long-term durability, better performance, and increased safety. The added benefits of improved air retention, better durability, and compatibility with TPMS often outweigh the higher initial cost.