Do you know how to properly install air hose connectors to avoid leaks?

2025.12.22

2025.12.22

Industry news

Industry news

Air hose connectors are critical components in air transmission systems. Proper installation not only ensures the efficient operation of the air system but also effectively prevents leakage problems.

1. Choose the Right Connectors

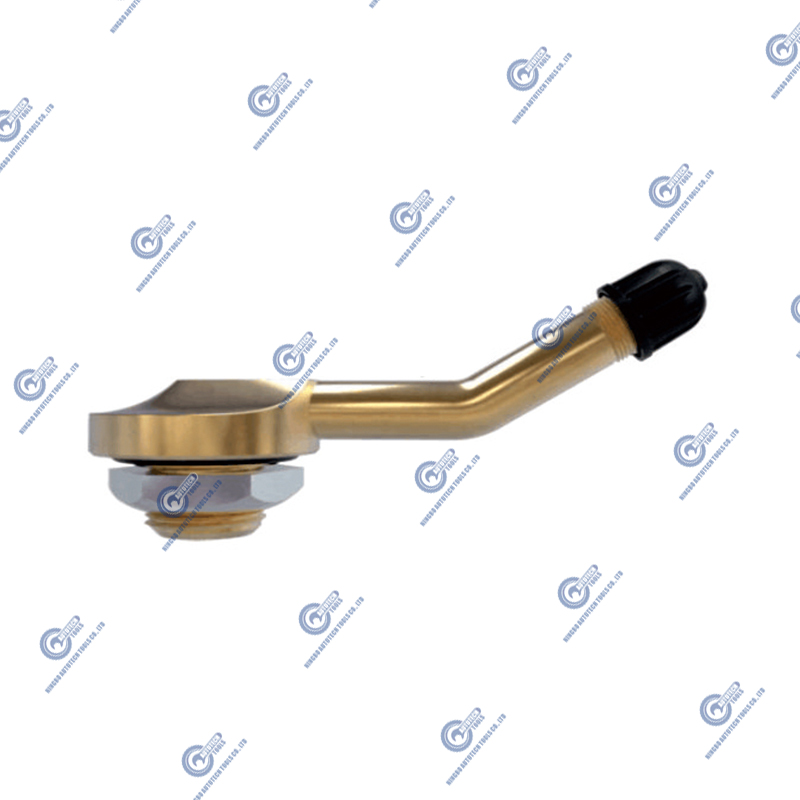

Choosing the right connector is the first step to ensuring that your air hose connection system remains leak-free. The size, material, and type of connector should match the specifications of the air hose. Ensure that the inner diameter of the air hose matches the size of the connector. Even if you manage to connect them, a mismatch can cause poor sealing and lead to leaks. The material of the connector is also crucial; common materials include stainless steel, brass, and aluminum. Each material has specific applications, such as stainless steel connectors being suitable for high-pressure environments, while brass connectors are often used in light industrial and low-pressure applications.

Make sure the connectors you choose are suited to the working environment of your air system. For example, if the system operates in high-temperature or chemically corrosive environments, it is important to select connectors that are resistant to high temperatures and corrosion.

2. Inspect the Quality of the Air Hose and Connectors

Before installation, it is essential to inspect both the air hose and connectors. Check the hose for any visible cracks, bends, or signs of aging, and make sure the connectors are not damaged or corroded. Using high-quality hoses and connectors can significantly reduce the risk of leaks. Additionally, ensure that the hose is cut cleanly and evenly; jagged cuts can lead to poor connections and leakage.

Also, check the O-rings on the connectors for wear. The O-ring plays a crucial role in preventing leaks. If the O-ring is damaged or missing, it should be replaced before installation.

3. Use PTFE Tape or Sealant

When installing threaded air hose connectors, using PTFE tape (Teflon tape) or a suitable sealant can significantly improve the seal. The proper method is to wrap the PTFE tape around the male threads of the connector, not the female threads. It’s recommended to use 2-3 layers of tape to ensure it evenly covers the threads, but make sure the tape does not hang over the edges, as this could obstruct airflow.

| Tape Type | Recommended Use | Advantages | Installation Tips |

|---|---|---|---|

| PTFE Tape | Threaded connections | Leak-proof, heat-resistant | Use 2-3 layers, avoid overhanging tape |

| Sealant | Non-threaded connections | Corrosion-resistant, long-lasting seal | Use moderate amount to avoid blockage |

| Adhesive Glue | Fixed connections | Strong connection | Choose adhesive suitable for temperature range |

When using PTFE tape or sealant, ensure it does not block the hose’s internal diameter. Excessive use can restrict airflow.

4. Hand-Tighten the Connector

During the installation process, start by hand-tightening the connector. This ensures that the threads are aligned correctly and there is no cross-threading. This step helps prevent damage or leakage caused by misaligned threads.

After hand-tightening, use a wrench to further tighten the connector, but avoid over-tightening. Over-tightening can damage the threads or connector. The ideal situation is that the connector is firmly seated against the hose, and only slight adjustments are needed. Tightening too much may not only damage the connector but also distort the hose, causing airflow restriction or leaks.

5. Check for Air Leaks

Once the connector is installed, it’s important to gradually pressurize the system and increase the airflow to normal operating pressure. Then, use soapy water or a dedicated leak detection solution to check each connection for bubbles. If bubbles appear, it indicates a leak that needs to be addressed. After detecting a leak, loosen and re-tighten the connector. If the issue persists, replace the faulty component.

If using soapy water, ensure it is non-corrosive to avoid damaging the equipment.

6. Regular Inspection and Maintenance

Even after proper installation, it is important to regularly inspect and maintain air hose connectors. Check the integrity of the O-rings, the wear and tear on the threads, and the condition of the hose, especially in high-pressure or high-temperature environments. Air hose connectors are subject to wear over time, which can affect their sealing performance.

FAQ Section

Q1: Why is there still a leak after installing air hose connectors?

A: The leak could be due to improper connector material, damaged O-rings, misaligned threads, or over-tightening during installation. Check if the connectors match the hose’s material, ensure O-rings are intact, and make sure the threads are properly aligned. Also, avoid excessive tightening.

Q2: How do I choose the right connector material?

A: When selecting connectors, consider the operating conditions of the system. For high-temperature or high-pressure environments, choose stainless steel connectors. For lighter loads, brass or aluminum connectors may be more suitable. Also, choose connectors based on corrosion resistance depending on the chemicals in the working environment.

Q3: How can I tell if the air hose connector is leaking?

A: Use soapy water or a dedicated leak detection liquid. If bubbles form, it indicates a leak. You can also listen for a continuous “hissing” sound, which suggests the air is leaking.

References

- “The Importance of Proper Fittings and Hose Connections,” Journal of Industrial Safety Engineering, 2022.

- “Air Hose and Fitting Installation: Best Practices,” Fluid Power Journal, 2021.

- “Leak Detection and Prevention in Pneumatic Systems,” Engineering Solutions, 2020.