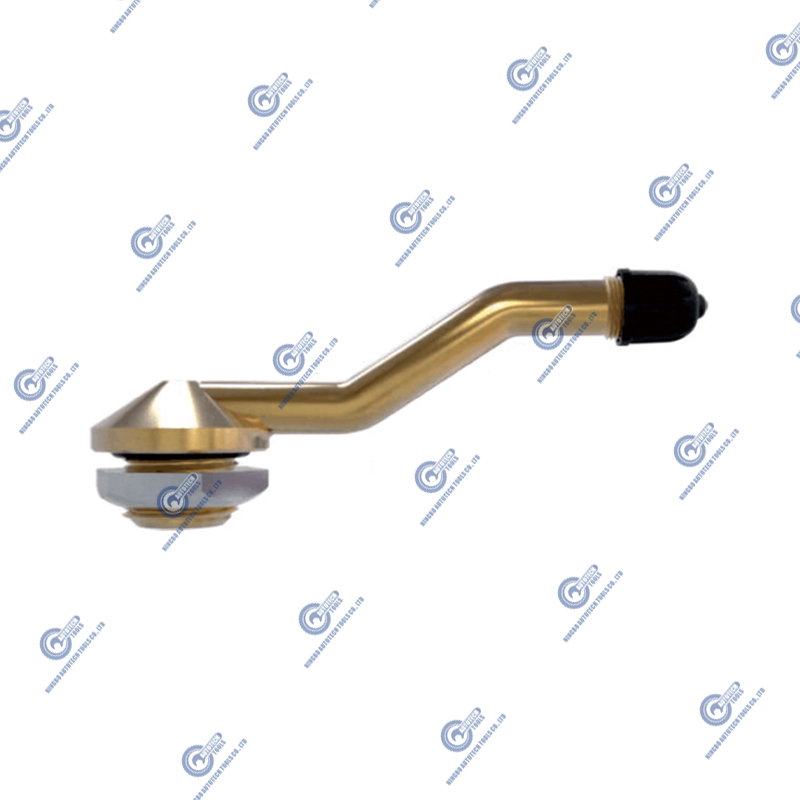

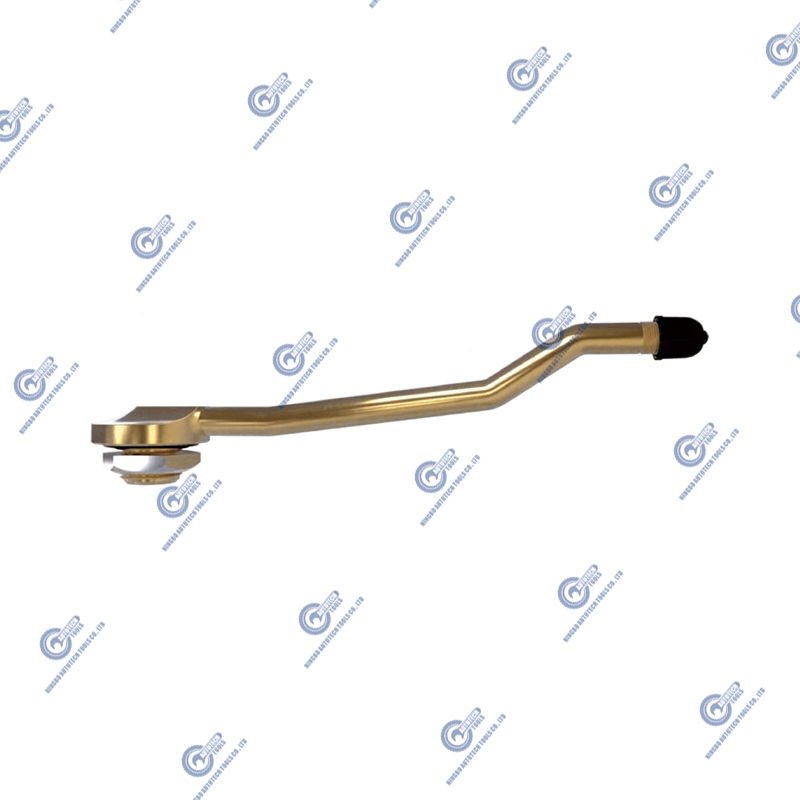

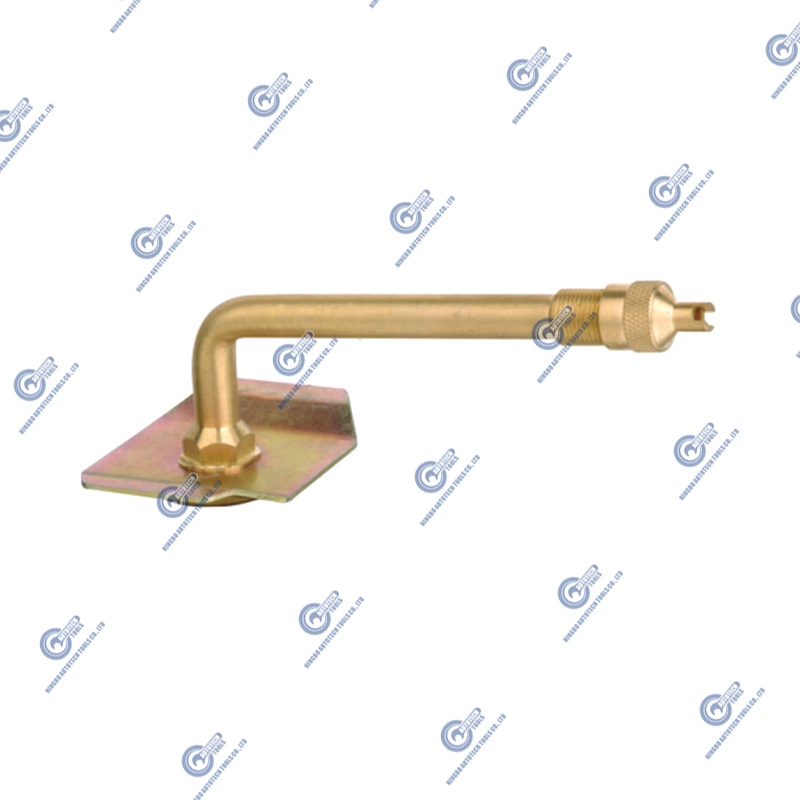

Why Are Rubber Base Valves Essential for Industrial Applications?

2025.11.17

2025.11.17

Industry news

Industry news

Rubber base valves play an important role in a variety of industrial systems, offering a unique set of advantages that contribute to efficiency, safety, and cost-effectiveness. The specific benefits of rubber base valves make them indispensable across industries that require robust, reliable, and adaptable fluid control solutions.

1. Durability and Resistance

Industrial environments are often harsh and demanding, requiring components that can withstand extreme conditions. Rubber base valves are designed to be highly durable, offering exceptional resistance to both physical wear and environmental factors.

Chemical and Corrosion Resistance

One of the standout characteristics of rubber base valves is their resistance to a wide range of chemicals and environmental elements. For instance, rubber compounds such as EPDM (Ethylene Propylene Diene Monomer) and Viton are commonly used because they can withstand exposure to acids, oils, solvents, and other aggressive substances. Unlike metal valves, which can corrode or degrade when exposed to harsh chemicals, rubber valves maintain their integrity, even in aggressive industrial environments such as petrochemical plants, water treatment facilities, and food processing plants.

Temperature Tolerance

Rubber base valves also have excellent resistance to temperature extremes. They can function in both high and low-temperature environments, making them suitable for industries that operate under varying thermal conditions. For example, certain rubber types can tolerate temperatures as low as -40°C and as high as 150°C, which is crucial in sectors such as cryogenics or high-temperature steam systems.

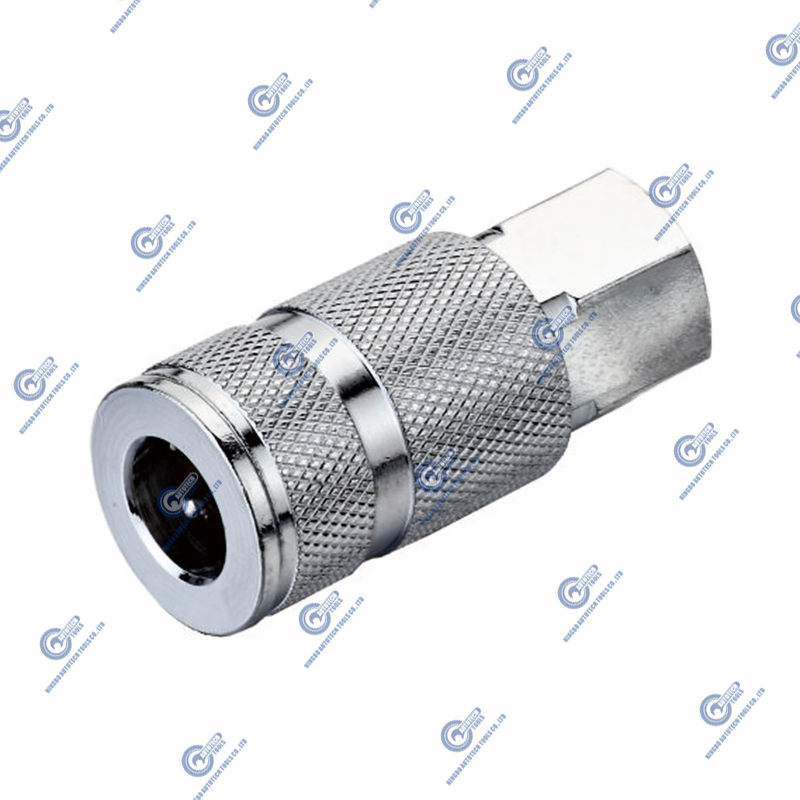

2. Sealing Capabilities

An effective seal is essential for controlling fluid flow and maintaining pressure within a system. Rubber base valves excel in this regard due to the inherent flexibility and elasticity of rubber materials.

Leak Prevention

The main function of a valve is to prevent leakage, and rubber base valves offer superior sealing capabilities. The soft, flexible rubber material allows for a tight, leak-proof seal that prevents fluids from escaping under pressure. This sealing ability is particularly critical in industries like oil and gas, where leakage of toxic or flammable substances can lead to catastrophic consequences.

Pressure Control

Rubber base valves provide excellent pressure control, which is crucial for systems that operate under varying or fluctuating pressures. The flexibility of rubber allows the valve to adjust and conform to the system’s requirements, ensuring stable pressure and preventing over-pressurization. This feature is especially important in hydraulic and pneumatic systems.

3. Flexibility in Design

Rubber base valves offer significant design flexibility, allowing them to be tailored to meet the specific needs of a given industrial application.

Customization

One of the advantages of rubber valves is that they can be molded into a variety of shapes and sizes. This customization is important for industries with unique or specialized requirements, such as food and beverage manufacturing, where contamination risks need to be minimized by using valves with specific dimensions and materials. Rubber base valves can be produced in a range of configurations to fit different pipe sizes, ensuring a precise match to the system.

Compatibility with Diverse Systems

Another key advantage of rubber base valves is their ability to work seamlessly with various fluid types. Whether the system involves water, oil, gas, or other industrial fluids, rubber base valves can be designed to handle them with ease, ensuring compatibility and preventing leaks or inefficiencies.

4. Noise and Vibration Reduction

In many industrial operations, noise and vibration can be a major issue. The movement of fluids through pipes, pumps, and valves can generate significant levels of noise and vibration, which can affect the operation of machinery and create an uncomfortable working environment. Rubber base valves are known for their ability to absorb these vibrations, contributing to quieter, more efficient operations.

Dampening Effects

The rubber material’s inherent ability to absorb shock and vibration helps to reduce the noise generated by moving fluids. In industries like automotive manufacturing, HVAC systems, and water treatment plants, minimizing noise pollution is essential for creating a better working environment and improving overall system performance.

Prevention of System Wear

In addition to reducing noise, rubber base valves also help prevent damage to equipment caused by excessive vibration. Constant vibration can lead to wear and tear on components, leading to premature failure. Rubber’s shock-absorbing properties help minimize this risk, ensuring that systems last longer and require less maintenance.

5. Cost-Effective Solution

When considering the total cost of a valve, it’s not just about the initial purchase price; long-term costs such as maintenance, energy consumption, and replacement must also be taken into account. Rubber base valves offer a cost-effective solution due to their longevity and ease of maintenance.

Lower Initial Costs

Rubber valves are typically more affordable than metal valves, both in terms of manufacturing and installation costs. This makes them an attractive choice for industries looking to cut initial expenses without sacrificing performance.

Reduced Maintenance and Replacement Costs

Rubber base valves often require less maintenance due to their durability and resistance to wear and tear. Unlike metal valves, which may corrode or fail prematurely, rubber valves maintain their functionality for longer periods, reducing the need for frequent replacements. This results in lower overall maintenance costs for industrial systems.

6. Improved Flow Control

Flow control is critical in many industrial systems, whether for regulating the movement of liquids, gases, or slurries. Rubber base valves can offer improved flow control compared to traditional valves.

Precision Control

Rubber base valves provide a high degree of precision in controlling the flow rate, especially in systems where small adjustments are required. Their soft, flexible construction allows for more accurate modulation of fluid flow, ensuring that systems operate within the desired parameters. This precision is particularly important in industries like pharmaceuticals, food processing, and chemical manufacturing.

Consistent Performance

In addition to precision, rubber base valves offer consistent performance over time. Unlike other valve types that may wear down and lose their ability to control flow effectively, rubber valves retain their flexibility and sealing properties throughout their lifecycle, ensuring long-term stability in fluid systems.

7. Resistance to Wear and Tear

Industrial environments, particularly those in mining, construction, and agriculture, can be rough on components like valves. These industries often work with abrasive materials or deal with high-stress conditions that can lead to premature wear. Rubber base valves are designed to resist this type of wear and tear.

Abrasion Resistance

The rubber materials used in these valves are highly resistant to abrasion, making them suitable for handling abrasive fluids and materials. This makes them ideal for applications in industries such as mining and construction, where the risk of damaging components with abrasive particles is high.

Extended Lifespan

Because of their ability to withstand wear, rubber base valves typically last longer than their metal counterparts in similar applications. This helps industries save on the cost of replacements and ensures that their systems continue to run smoothly over extended periods.

8. Versatile Applications

Rubber base valves are highly versatile, used in a broad range of industries for various applications. Their flexibility in design and functionality makes them suitable for nearly every type of fluid control system.

Common Industries

Industries that commonly use rubber base valves include:

- Water Treatment: Ensuring efficient flow control and leak prevention.

- Oil and Gas: Providing durable, resistant valves for harsh, high-pressure systems.

- Food and Beverage: Offering sanitary, leak-free solutions that meet hygiene standards.

- Chemical Processing: Withstanding exposure to corrosive chemicals and extreme temperatures.

Wide Range of Fluids

Rubber base valves can be used to control the flow of a wide variety of fluids, including water, oils, slurries, gases, and chemicals. This versatility allows industries to implement rubber valves across multiple processes with different fluid types and flow conditions.

9. Energy Efficiency

Energy consumption is a major concern for many industrial operations, especially in energy-intensive industries like manufacturing, oil and gas, and power generation. Rubber base valves can help improve the energy efficiency of fluid systems.

Optimized Pressure Management

Rubber base valves help maintain optimal pressure within systems, preventing energy loss. Stable pressure management reduces the need for additional power to compensate for pressure drops, resulting in lower energy consumption and reduced operational costs.

Reduced Power Loss

Because rubber valves ensure tight seals and precise flow control, they help reduce power losses that could occur due to leaks or inconsistent flow. This contributes to the overall energy efficiency of the system.

10. Environmental Protection

In industries where hazardous fluids or gases are handled, preventing leaks and spills is critical for environmental protection. Rubber base valves play an important role in ensuring that these substances are safely contained.

Leak Prevention

The tight seals offered by rubber valves significantly reduce the risk of fluid leakage. This is particularly important in industries like oil and gas, where even a small leak can have significant environmental consequences.

Compliance with Regulations

Rubber base valves help industries meet environmental regulations by ensuring that no hazardous materials are released into the surrounding environment. Their superior sealing capabilities contribute to compliance with safety and environmental protection standards.