How to choose the right Rubber Base Valve: ensuring sealing performance and durability

2025.09.29

2025.09.29

Industry news

Industry news

1. Material Selection: Ensuring Optimal Sealing Performance

Characteristics of Different Rubber Materials

Choosing the right rubber material is critical in determining the performance of a Rubber Base Valve. Different types of rubber materials have different physical properties and durability, so it is essential to choose the most suitable material based on the working environment. Below are the common rubber materials and their characteristics:

Natural Rubber (NR)

Natural rubber is one of the most common types and has good elasticity and wear resistance. It is relatively inexpensive and suitable for normal temperature and normal pressure environments. However, natural rubber has poor oil resistance and is not suitable for fluids containing oil or other chemicals.

Nitrile Rubber (NBR)

Nitrile rubber is well-known for its excellent oil resistance and wear resistance. It is ideal for sealing in environments involving oil, lubricants, and other petroleum-based fluids. Nitrile rubber also offers high resistance to abrasion, allowing it to withstand higher pressures and temperatures.

Fluorocarbon Rubber (FKM)

Fluorocarbon rubber is highly heat-resistant and has chemical stability, capable of withstanding temperatures up to 250°C. It is excellent for applications requiring strong chemical resistance, particularly against acids, alkalis, and solvents. However, fluorocarbon rubber is more expensive and is generally used in applications that demand superior performance.

Neoprene Rubber (CR)

Neoprene rubber has good resistance to heat, oil, and ozone. It is suitable for high-temperature applications and environments requiring strong sealing performance. It is widely used in marine and shipbuilding industries.

How to Choose the Right Material

When choosing a material, consider factors such as working temperature, pressure, and the type of fluid in the system. For high-temperature or high-pressure environments, choose materials like fluorocarbon rubber or silicone rubber, while nitrile rubber is best for oil-based fluids.

2. Valve Design: Meeting Pressure and Flow Demands

Valve Design Types

Different Rubber Base Valve designs suit different installation needs, and choosing the right design ensures the valve performs optimally in the system. Common design types include:

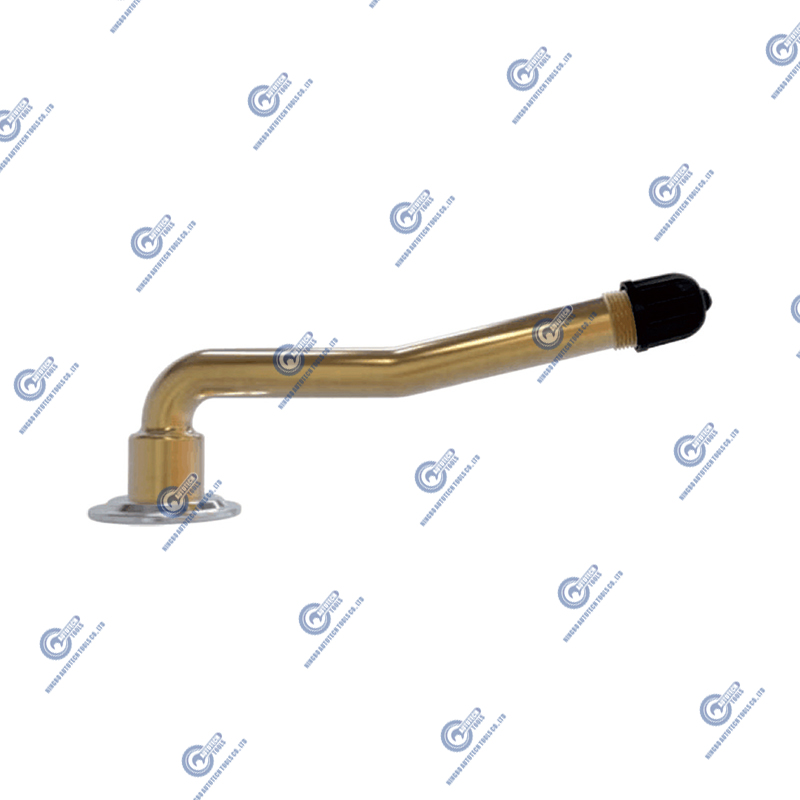

Straight-through Valve

Straight-through Rubber Base Valves are commonly used for simple fluid control. Their design is relatively simple, and fluid passing through causes minimal pressure loss, ensuring good flow control. This design is suitable for medium to low-pressure systems, ideal for standard operational conditions.

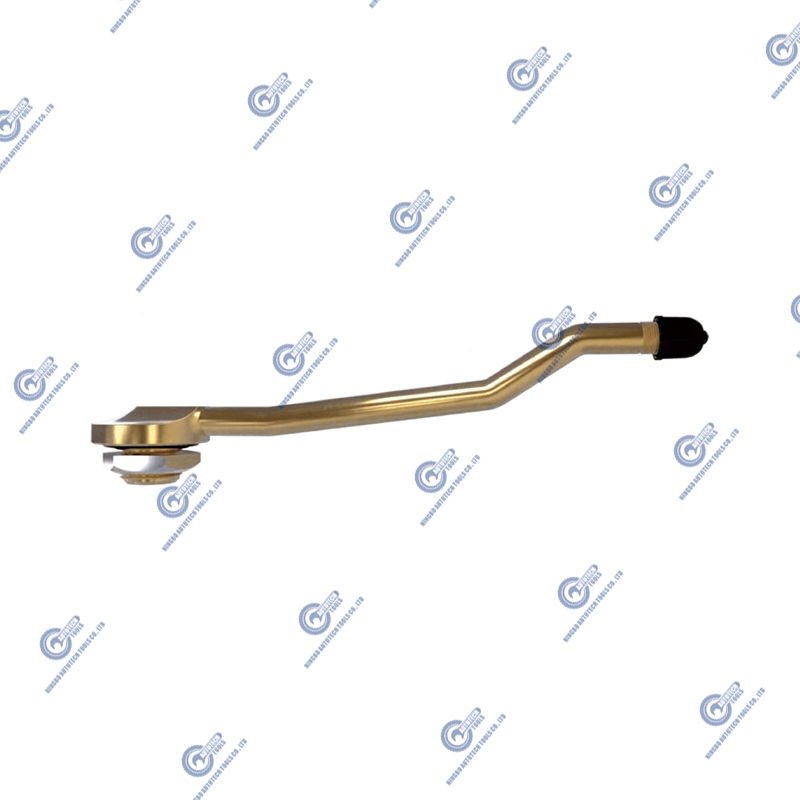

Angle Valve

Angle Rubber Base Valves are used in systems where fluid direction needs to be changed. The design allows the flow to be redirected, and is particularly useful in systems with multi-directional flow. Compared to straight-through valves, they typically incur slightly higher pressure losses but are ideal for installations in tight spaces.

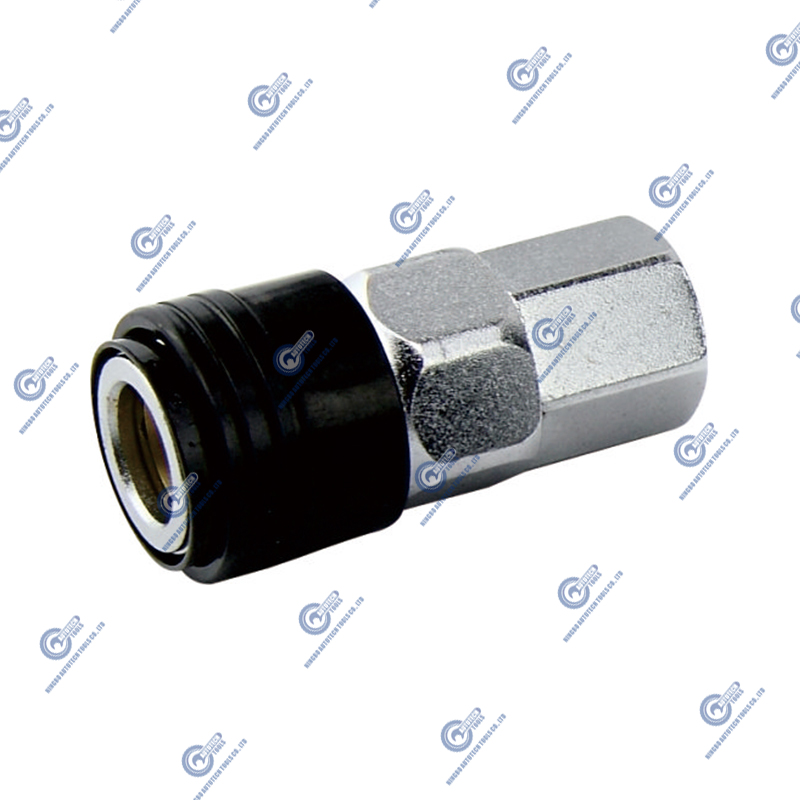

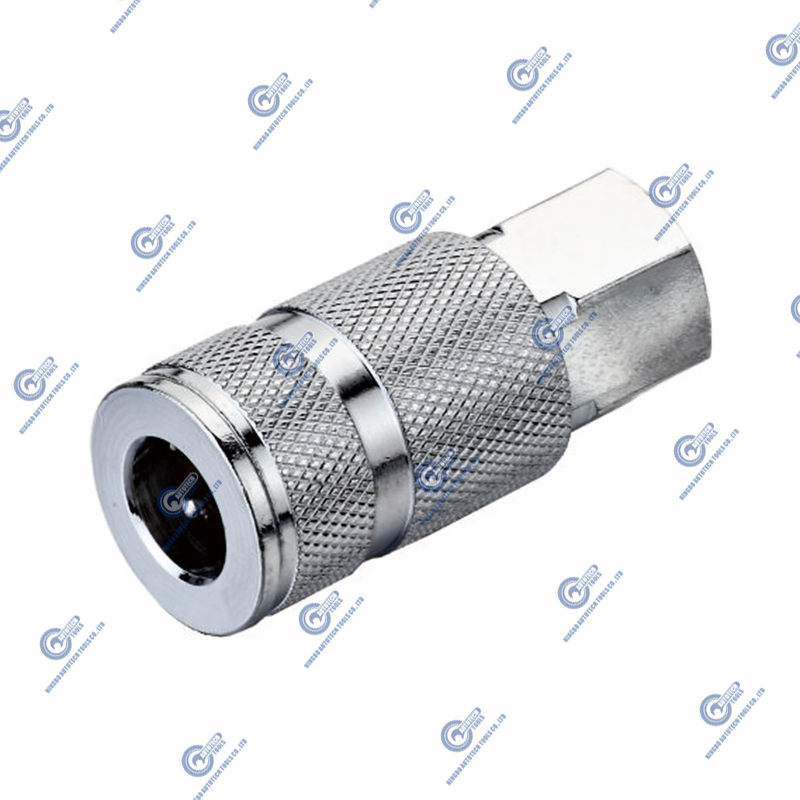

Ball Valve

Ball Rubber Base Valves offer excellent sealing performance, making them ideal for precise flow control and leak prevention. Their strong sealing ability makes them suitable for high-pressure and high-flow systems.

Adapting to Different Pressure and Flow

When selecting a Rubber Base Valve, consider the working pressure and flow requirements of the system. For high-pressure systems, choose valves that can withstand higher pressures, typically by increasing valve wall thickness or using reinforced seals. For high-flow systems, choose valves with lower resistance to ensure smooth fluid flow.

3. Sealing Performance: Minimizing Leak Risks

Importance of Sealing Design

Sealing performance is one of the key characteristics of Rubber Base Valves, and selecting a high-quality sealing design is crucial in preventing fluid leakage and reducing the risk of system failure. Common sealing designs include:

Static Seals

Static seals are used in valves where the sealing parts do not experience relative movement during valve operation, making them suitable for systems with lower pressures or more stable working environments. Common static seal materials include rubber gaskets and PTFE.

Dynamic Seals

Dynamic seals are designed to seal valves where relative movement occurs during operation. These seals require high wear resistance and elasticity, with materials like fluorocarbon rubber and PTFE commonly used.

Choosing the Right Sealing Performance

Select sealing materials based on the working environment of the system. For low-temperature or high-temperature environments, fluorocarbon rubber or silicone rubber is ideal, while EPDM rubber and NBR are commonly used in standard environments.

4. Corrosion and Wear Resistance: Extending Service Life

Corrosion Resistance

In many applications, Rubber Base Valves are exposed to corrosive fluids, such as strong acids, alkalis, or saltwater. In these cases, it is essential to choose materials with strong corrosion resistance. For example, fluorocarbon rubber and PTFE offer excellent chemical stability and can effectively resist most corrosive substances.

Wear Resistance

In high-pressure and high-flow systems, the sealing components of the valve may experience friction with the fluid, leading to wear. Therefore, choosing materials with high wear resistance helps prolong the valve’s service life. Nitrile rubber and fluorocarbon rubber both exhibit excellent wear resistance and are suitable for high-load working conditions.

Balancing Corrosion and Wear Resistance

In complex applications, valves need to possess both corrosion resistance and wear resistance. In such cases, composite materials, such as PTFE coatings or fluorocarbon rubber coatings, can offer enhanced performance.

5. Environmental Adaptability: Choosing the Right Temperature and Environment

High-Temperature Environments

Rubber Base Valves used in high-temperature environments must be able to withstand high heat. Fluorocarbon rubber, silicone rubber, and neoprene rubber are suitable materials for these conditions, as they can maintain good sealing performance and stability at high temperatures.

Low-Temperature Environments

For low-temperature applications, the Rubber Base Valve should have good low-temperature flexibility. Materials such as EPDM rubber and fluorocarbon rubber maintain flexibility at low temperatures, preventing cracking and ensuring effective sealing performance.

6. Maintenance and Inspection: Easy for Regular Servicing

Importance of Regular Maintenance

Regularly checking the working condition, sealing performance, and any cracks or wear in the Rubber Base Valve helps extend its service life. During maintenance, it is crucial to inspect the seals for wear and replace them as needed.

Effective Maintenance Practices

- Check Valve Sealing: Regularly inspect the sealing components for leaks.

- Clean the Valve Interior: Periodically clean the valve interior to prevent debris from blocking it.

- Replace Seals: When seals show signs of aging or wear, replace them promptly.

7. Choosing the Right Brand and Supplier

Brand Reputation and Quality Assurance

Choosing a well-known brand ensures more reliable quality and better after-sales service. When selecting a Rubber Base Valve, consider the supplier’s product certifications, customer reviews, and after-sales support. Reputable brands typically maintain rigorous standards in material selection, production processes, and product testing.