What Are the Key Benefits of Using Quick Connect Couplings in Fluid Systems?

2025.10.27

2025.10.27

Industry news

Industry news

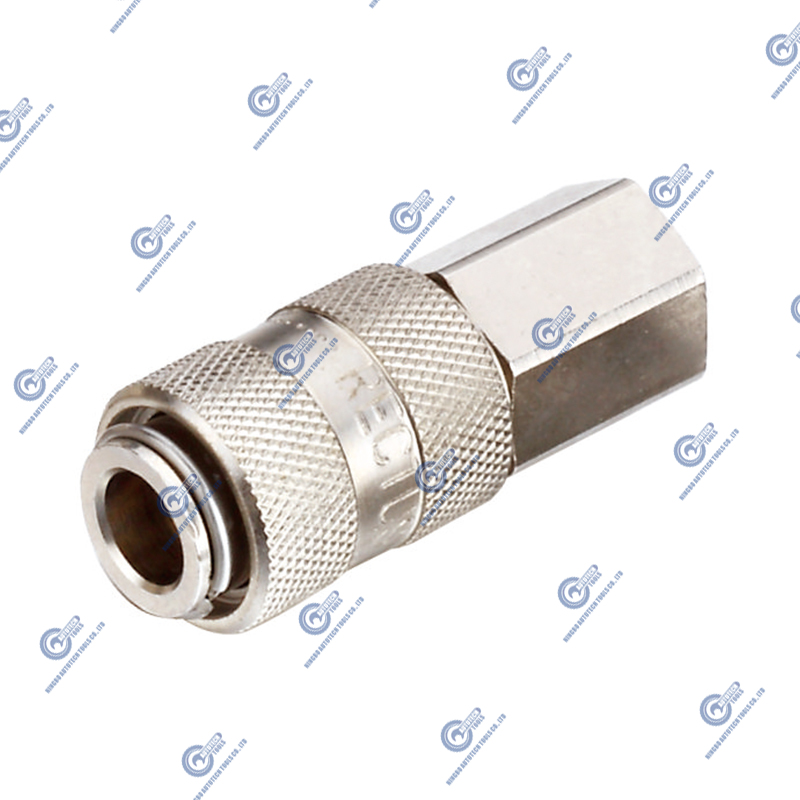

Quick connect couplings are vital components in modern fluid systems, offering a variety of benefits in both industrial and commercial applications. These couplings are designed to quickly connect and disconnect fluid lines with minimal effort, which improves efficiency and safety.

1. Time Efficiency

Time is one of the most critical factors in any industrial or fluid-handling system. Quick connect couplings are designed to save time by allowing operators to quickly and easily connect and disconnect fluid lines. This is especially crucial in industries like manufacturing, automotive, and agriculture, where downtime can be costly.

How Quick Connect Couplings Save Time:

-

No Tools Required: Unlike traditional methods that require tools such as wrenches or screwdrivers, quick connect couplings are engineered for tool-free operation. The design allows operators to simply push, click, or twist to make a secure connection. This eliminates the need for additional setup or teardown time.

-

Reduced Downtime: In fluid systems where fluid lines need to be connected and disconnected frequently, quick connect couplings significantly reduce the amount of time spent on these tasks. Whether during routine maintenance or system upgrades, operators can perform these tasks much faster, thus minimizing downtime.

-

Ideal for Frequent Changes: In certain systems that require frequent line changes, such as mobile equipment or cleaning processes, quick connect couplings allow operators to move from one connection to another almost immediately. This enhances overall system flexibility.

Example:

In an industrial factory, the use of quick connect couplings can reduce the time spent on cleaning equipment by up to 50%. The faster connection and disconnection process allows the factory to move from one task to another without long delays.

2. Improved Safety

Quick connect couplings are specifically designed with safety in mind. They reduce the risks associated with fluid systems, particularly in environments where fluids can be hazardous or under high pressure.

Safety Features of Quick Connect Couplings:

-

Automatic Shut-Off Valves: Many quick connect couplings come equipped with shut-off valves that automatically stop fluid flow when the coupling is disconnected. This prevents spills, leaks, or accidents when changing or removing connections. The automatic shut-off feature ensures that operators are not exposed to hazardous fluids.

-

Pressure Resistance: Quick connect couplings are built to withstand high pressures. Whether the system involves pressurized air, hydraulic fluids, or other high-pressure liquids, these couplings can hold up against the pressure without failure. This minimizes the risk of sudden leaks or ruptures that could result in injuries or system damage.

-

Ergonomics and Ease of Use: The design of quick connect couplings is ergonomically friendly, allowing operators to make secure connections without excessive force. This reduces the risk of injury that could occur with hand tools or over-tightening traditional connections.

Example:

In the case of high-pressure hydraulic systems, quick connect couplings with integrated pressure release valves prevent sudden discharges of pressurized fluids, reducing the risk of explosions or injuries during maintenance.

3. Enhanced Durability

Quick connect couplings are built to last. They are made from durable materials that can withstand harsh industrial environments. This makes them a cost-effective choice in the long run, as they reduce the need for frequent replacements.

Material Considerations for Durability:

-

Stainless Steel: Many high-performance quick connect couplings are made from stainless steel, which offers resistance to corrosion and extreme temperatures. This is ideal for applications where the coupling is exposed to harsh chemicals or outdoor conditions.

-

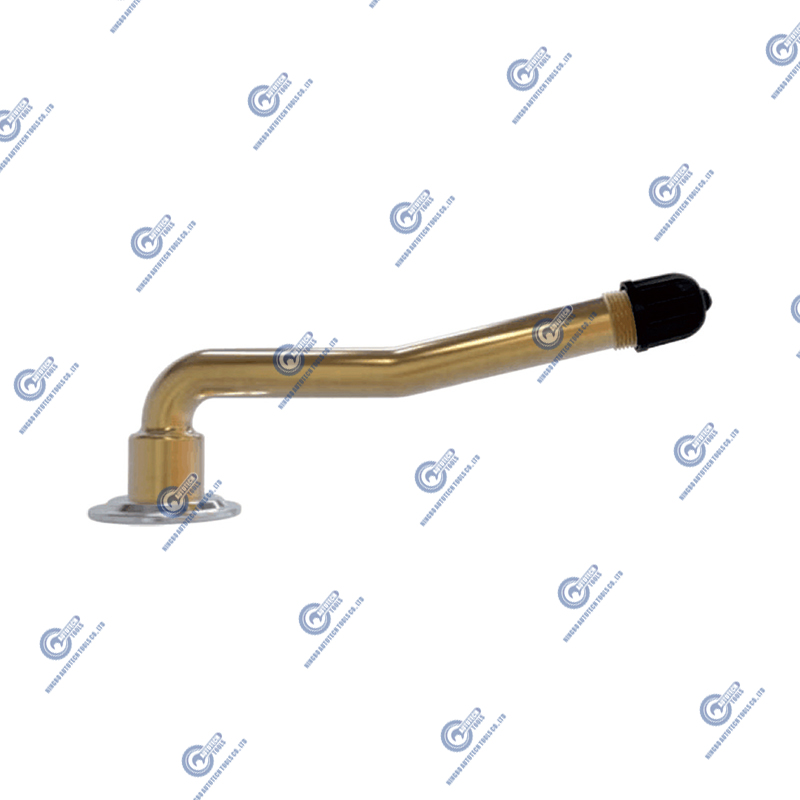

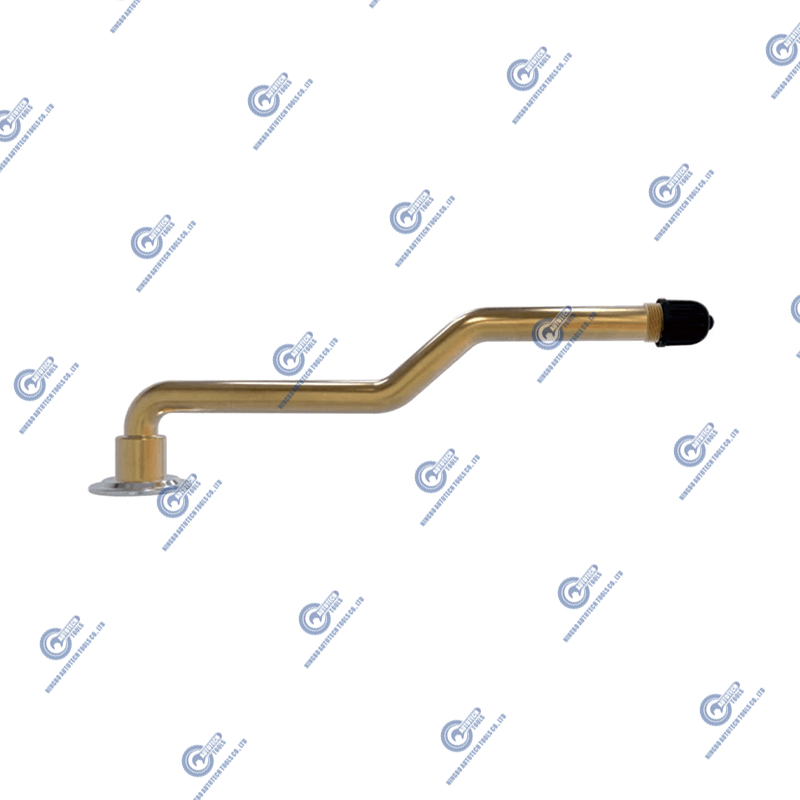

Brass and Aluminum: Some couplings are made from brass or aluminum, which offer excellent durability while being lightweight. These materials are also resistant to corrosion and offer a balance between strength and ease of installation.

-

Thermoplastics: In certain fluid systems, thermoplastic quick connect couplings are used because they provide high chemical resistance and flexibility, even at lower weights. This makes them ideal for use in systems where weight is a concern, such as in aerospace or automotive applications.

Example:

In the food and beverage industry, stainless steel quick connect couplings are used extensively because they can withstand the acidic and caustic environments often found in food processing plants, reducing the risk of corrosion and improving longevity.

4. Versatility in Applications

Quick connect couplings are extremely versatile and can be used in a variety of industries and systems. Their ability to handle a wide range of fluids, from oils and gases to water and chemicals, makes them a popular choice for a broad spectrum of applications.

Applications Across Industries:

-

Hydraulic Systems: In hydraulic systems, quick connect couplings make it easier to switch between different tools or machines. They allow operators to quickly change attachments or disconnect hoses for maintenance.

-

Agriculture: In farming and agricultural machinery, quick connect couplings are used to quickly attach and detach irrigation hoses or sprayers. This reduces the time spent on setup and increases overall productivity.

-

Medical Equipment: Quick connect couplings are also used in medical devices and equipment, where safety and precision are paramount. They are used to connect medical gas lines, allowing for quick and secure connections.

-

Manufacturing: In manufacturing plants, quick connect couplings are used to connect fluid lines for cooling systems, pressure testing equipment, and more. Their ease of use and reliability make them essential for maintaining high-efficiency standards.

Example:

In agricultural equipment, the use of quick connect couplings allows for fast attachment and detachment of spraying units, improving operational efficiency during planting and harvesting seasons.

5. Reduced Risk of Human Error

Manual connections often introduce human error. Quick connect couplings are designed to be foolproof, reducing the chance of improper installation, over-tightening, or connection failure.

How Quick Connect Couplings Minimize Human Error:

-

Self-Locking Mechanisms: Many quick connect couplings feature self-locking designs that automatically secure the coupling once it is connected. This ensures that operators do not have to worry about manually tightening or checking connections.

-

Clear Indicators: Some designs come with visual or tactile indicators that signal when a coupling is properly connected. This allows operators to easily confirm that the connection has been made without having to check with additional tools.

-

Consistency: Quick connect couplings provide consistent performance each time they are connected. Operators can trust that the connection will be secure, which is not always the case with manual methods.

Example:

In the automotive industry, quick connect couplings are used to attach various parts of the fuel system. The self-locking design ensures that operators do not over-tighten the connections, reducing the risk of leaks and improving system reliability.

6. Leak Prevention

One of the primary benefits of quick connect couplings is their ability to prevent leaks and spills, which are critical in fluid systems where environmental and safety concerns are paramount.

How Leak Prevention Works:

-

Sealing Features: Most quick connect couplings have integrated seals or O-rings that prevent leaks during the connection or disconnection process. These seals ensure that no fluid escapes, even when under pressure.

-

Valve Systems: Some couplings are designed with internal valves that stop the flow of fluids when disconnected. This minimizes the risk of fluid leakage, which is especially important in systems that involve hazardous chemicals or expensive fluids.

-

Pressure Relief: Certain quick connect couplings have pressure relief mechanisms built in, which ensure that pressure is safely released before disconnecting, further reducing the potential for leaks or spills.

Example:

In chemical plants, quick connect couplings with advanced sealing mechanisms are used to prevent leaks during the transfer of hazardous substances. The sealed couplings ensure that there is no environmental contamination.