Why high-performance cars tend to use clamp-in tire valves

2025.09.01

2025.09.01

Industry news

Industry news

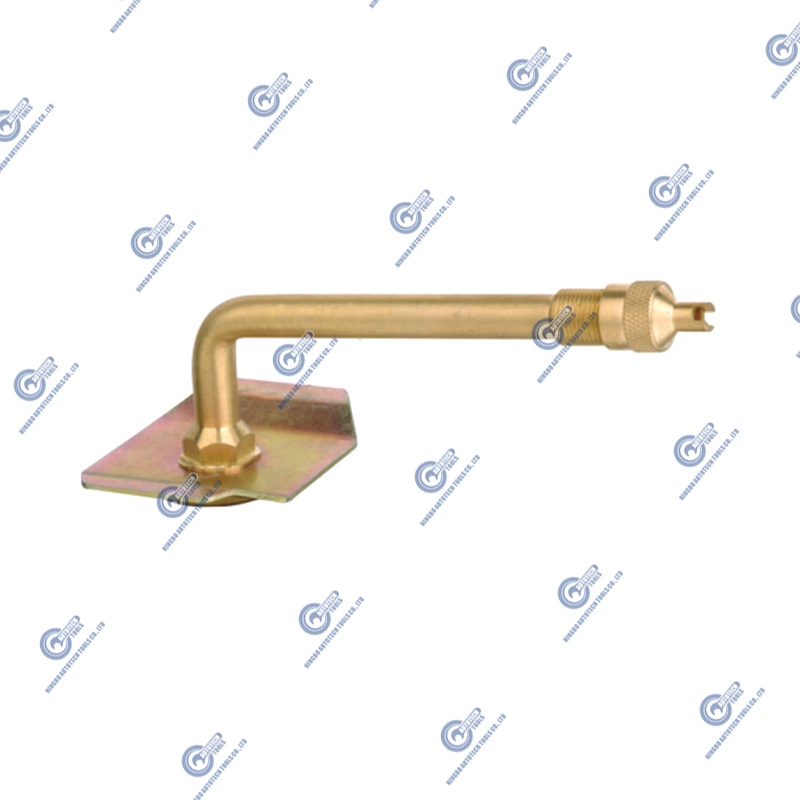

1. Structure and Features of Clamp-in Tire Valves

Clamp-in tire valves are typically made of metal (such as brass, stainless steel, or aluminum alloy). The main body is secured to the wheel hub via a nut, creating a stable mechanical locking structure.

High-strength material: Metal is less susceptible to aging and cracking than rubber and can withstand higher tire pressures.

Nut-clamping design: Mechanical tightening ensures excellent sealing performance.

Corrosion-resistant treatment: Most products are electroplated or anodized to extend their service life.

Aesthetics: They offer a more refined design and are often paired with high-end wheels, meeting the aesthetic requirements of high-performance vehicles.

These features make clamp-in tire valves not only functional but also a choice that balances performance and design.

2. Special Requirements of High-Performance Vehicles

During operation, high-performance vehicles experience tires subjected to far more demanding conditions than ordinary vehicles:

High-speed tire pressure fluctuations: At high speeds, the internal temperature of the tire rises, and air expands, causing a significant increase in tire pressure, placing even higher demands on the valve's sealing performance. High-Temperature Environments: During racetracks or long-distance high-speed driving, tire temperatures can exceed 100°C, and ordinary rubber bead valves may soften or crack.

Lightweight and aesthetically pleasing: High-performance vehicles strive not only for speed and handling but also emphasize overall vehicle design, thus preferring metal bead valves that blend seamlessly with the wheel's texture.

These factors make traditional rubber bead valves inadequate, making clamp-in tire valves an ideal alternative.

3. Advantages of Clamp-in Tire Valves

High-Pressure Resistance

Clamp-in bead valves can withstand tire pressures of 65 psi or higher, while rubber bead valves are typically only suitable for use below 50 psi. This is particularly important for sports cars and SUVs that use high tire pressures.

High-Temperature Resistance

The metal structure remains stable in high-temperature environments and will not deform or age due to heat like rubber, ensuring long-term airtightness.

Strong Airtightness

The nut-clamping design provides a secure bond between the valve and the wheel, making it less susceptible to leaks due to vibration or temperature fluctuations. Excellent Durability

Metal material generally lasts far longer than rubber, making it particularly suitable for luxury and track-used vehicles with long-term use, reducing tire replacement frequency.

Excellent Visual Effect

High-performance vehicle owners often prioritize exterior details. Metal tire beading complements aluminum alloy wheels for a more integrated look and is commonly found on modified vehicles and luxury brands.

4. Practical Application Scenarios

Track driving: High-speed corners and prolonged high-speed driving cause tire pressure and temperature to rise continuously. Clamp-in tire beading effectively prevents flats.

Long-distance high-speed driving: Stability and durability are extremely demanding, and metal tire beading reduces the risk of sudden failure.

Low-profile tires: High-performance vehicles often feature low-profile tires, requiring higher tire pressures. Clamp-in tire beading provides better support.

Luxury and modified vehicles: Beyond performance, the aesthetic advantages of metal tire beading also appeal to these vehicles.

5. Potential Disadvantages and Considerations

Higher Cost: Clamp-in tire beading is several times more expensive than rubber tire beading, making it considered a "high-end feature." High installation requirements: Requires professional installation and a torque tool. Failure to do so can lead to seal failure due to overtightening or undertightening.

Regular inspection: While the tire lifespan is extended, it's still necessary to check the tightness of the nuts when changing tires or performing tire maintenance to ensure a tight seal.