Are Your European Interchange Couplings Truly Compatible with ISO 7241 Standards?

2026.02.02

2026.02.02

Industry news

Industry news

In the highly fragmented global market for hydraulic components, the term European Interchange Couplings is frequently used as a broad marketing label, but for a maintenance engineer or an equipment manufacturer (OEM), it represents a specific set of rigorous mechanical requirements. In Europe, where hydraulic systems are foundational to the agricultural, construction, and manufacturing sectors, the ISO 7241 standard serves as the vital framework ensuring that components from different manufacturers can work together without risk. However, true compatibility extends far beyond the ability to physically connect a male and female coupler. It encompasses the precision of the poppet valve alignment, the tolerance of the locking balls, and the material integrity under high-pressure impulses. As businesses look to optimize their supply chains and reduce procurement costs, understanding whether their “interchangeable” couplings actually meet international standards is critical for preventing catastrophic system failures and costly environmental cleanups.

The Architecture of ISO 7241: Series A vs. Series B Standards

To navigate the world of hydraulic quick disconnects, one must first master the two primary pillars of the ISO 7241 specification: Series A and Series B. While both fall under the same standard, they are engineered for entirely different operational environments and pressure profiles. For European-based machinery, the distinction is even more pronounced due to historical regional design preferences. Failing to identify the correct series is one of the leading causes of “wrong-part” procurement and subsequent hydraulic leaks in the field.

ISO 7241 Series A: The Heart of European Agricultural Machinery

The ISO 7241 Series A is the quintessential European profile, widely recognized as the standard for agricultural tractors and mobile machinery. Originally popularized by manufacturers like Faster and Parker, this profile was adopted by ISO to ensure that a tractor manufactured in Germany could seamlessly operate an attachment built in Italy or France. The technical brilliance of Series A lies in its poppet valve design, which is engineered for maximum flow and minimal pressure drop. However, true ISO 7241-A compatibility requires more than just a matching shape. It requires that the “nose” of the male nipple has a specific 45-degree angle and that the internal valve remains fully open even under high flow rates. In recent years, many “off-brand” European interchange couplings have entered the market with slight dimensional deviations. While these may connect to an ISO 7241-A socket, they often restrict the valve’s travel, leading to localized turbulence and a significant increase in hydraulic oil temperature, which eventually degrades the system’s seals and performance.

ISO 7241 Series B: Precision in Industrial and Chemical Applications

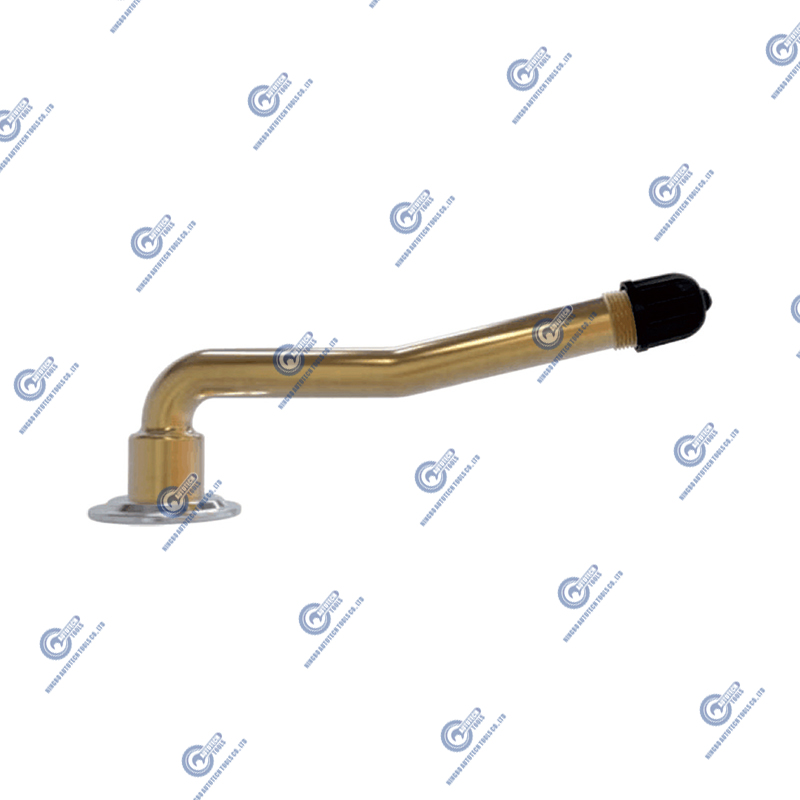

While Series A dominates the open fields, ISO 7241 Series B is the standard of choice for European industrial plants, chemical processing units, and high-precision manufacturing lines. The Series B profile is generally more compact and is designed to handle a wider variety of fluids beyond standard mineral oils. Because industrial applications often involve corrosive chemicals or high-temperature washdowns, Series B couplings are frequently manufactured from high-grade stainless steel or brass. The interchangeability within Series B is equally strict; a “European interchange” claim must be backed by data confirming that the locking groove dimensions match the ISO 7241-B blueprint exactly. A common mistake in the industry is assuming that a Series B coupling is simply a smaller version of Series A. In reality, they are two distinct mechanical systems with different ball-locking configurations and seal placements. For those managing complex industrial fluid power systems, ensuring a consistent Series B inventory is essential for minimizing downtime and ensuring workplace safety.

The Risks of Non-Standard Interchange Couplings in High-Pressure Systems

In the world of high-pressure hydraulics, “close enough” is never good enough. When a coupling is marketed as a “European interchange” without a verified ISO 7241 certification, the user is assuming a massive amount of operational and financial risk. The coupling is the most vulnerable point in any hydraulic circuit, and even a microscopic mismatch in the mating surfaces can lead to a chain reaction of failures that compromise the entire machine.

Hydraulic Turbulence, Friction, and System Overheating

The most insidious effect of using a non-compliant interchange coupling is the hidden damage caused by internal turbulence. When a male nipple and a female socket are not perfectly aligned according to ISO 7241 standards, the internal poppet valves may not open completely. This creates a “throttling” effect similar to a partially closed faucet. As hydraulic fluid is forced through this restricted opening, its velocity increases exponentially, creating the Venturi effect. This turbulence generates significant amounts of heat. In a high-cycle hydraulic system, this localized heating can raise the overall temperature of the hydraulic reservoir. Overheated oil loses its viscosity, which means it can no longer provide adequate lubrication to the pumps and cylinders. If you find that your European equipment is running hot or that your pump life is shorter than expected, the culprit is often a mismatched “interchange” coupling that is acting as a permanent heat generator in your lines.

Brinelling and the Danger of Forced Disconnection

Beyond performance issues, there is a severe safety risk associated with material quality in uncertified couplings. Brinelling is a term used to describe the permanent indentation of the locking balls into the metal surface of the male nipple. True ISO 7241 compliant couplings are made from case-hardened steel to prevent this phenomenon. However, inferior “interchange” models often use softer metals. Under the intense pressure of a hydraulic pulse, the locking balls can “dig into” the nipple, effectively freezing the coupling so it can no longer be disconnected. Worse yet, in some cases, the pressure can cause the nipple to be ejected from the socket with enough force to cause severe property damage or fluid injection injuries to nearby workers. By insisting on couplings that meet the ISO pressure impulse requirements, you are not just buying a connector; you are investing in a safety-critical component that has been tested to withstand 1.33 times its working pressure for over 200,000 cycles.

Technical Specifications for ISO 7241-A European Couplings

To assist in your procurement and engineering selection, refer to the following table for the technical benchmarks of true ISO 7241 Series A compatibility in standard European sizes.

| Nominal Size (Inch) | ISO Size (DN) | Max Working Pressure (Steel) | Min Burst Pressure | Flow Rate (L/min) |

|---|---|---|---|---|

| 1/4" | DN6.3 | 350 Bar / 5075 PSI | 1400 Bar | 12 L/min |

| 3/8" | DN10 | 300 Bar / 4350 PSI | 1200 Bar | 23 L/min |

| 1/2" | DN12.5 | 250 Bar / 3625 PSI | 1000 Bar | 45 L/min |

| 3/4" | DN20 | 250 Bar / 3625 PSI | 1000 Bar | 100 L/min |

| 1" | DN25 | 230 Bar / 3335 PSI | 920 Bar | 190 L/min |

Frequently Asked Questions (FAQ)

Can I mix a Series A male with a Series B female coupling?

No. Despite falling under the same ISO 7241 umbrella, Series A and Series B have entirely different dimensional profiles and internal valve geometries. They are physically incapable of mating, and attempting to force a connection will damage the locking mechanism and cause a catastrophic leak.

How do I identify a “German” or “Italian” standard coupling?

Most European standards are now harmonized under ISO 7241-A. However, if your coupling has a flat mating surface, it is likely an ISO 16028 Flat Face coupling, which is a different standard entirely. For poppet-style couplings, measuring the nipple’s outside diameter and comparing it to the table above is the best way to verify the size.

Why is stainless steel preferred for some European interchanges?

In Europe, many industrial applications involve aggressive cleaning agents or exposure to coastal saltwater environments. Stainless steel (AISI 316) offers superior corrosion resistance compared to standard zinc-plated carbon steel, ensuring that the coupling does not “seize” over time.

Technical References and Industrial Standards

- ISO 7241:2014: Hydraulic fluid power — Dimensions and requirements of quick-action couplings.

- DIN 24320: European standards for fire-resistant hydraulic fluids and compatible sealing materials.

- SAE J1036: Standard for hydraulic pressure ratings and testing for agricultural tractor applications.

- ISO 16028: Hydraulic fluid power — Flush-face type, quick-action couplings for use at pressures up to 31.5 MPa.