Top 5 Benefits of Using Couplers and Plugs in Compressed Air Applications

2025.07.21

2025.07.21

Industry news

Industry news

1. Secure and Leak-Free Connections

In compressed air applications, it is critical to ensure that the connection is secure and leak-free. Couplers and plugs provide a simple and effective way to maintain connections between equipment that can withstand high pressures and ensure that there are no air leaks during operation. If a leak occurs in the air system, it will not only result in air waste, but may also cause unstable performance or even damage to the tool or equipment.

High-quality coupler and plug systems use advanced sealing technology and high-precision design to provide a long-lasting seal to prevent air from leaking out. This sealing performance is especially important for high-pressure systems, because any small leak will affect the air flow and pressure, thereby affecting the efficiency of the equipment.

Couplers and plugs can also reduce the energy consumption of the system. Because there are no leaks, the compressor does not need to increase power unnecessarily to compensate for leaks, avoiding energy waste.

2. Quick and Easy Coupling/Decoupling

In many industrial environments, efficient equipment conversion and quick tool replacement are key to improving work efficiency. By using couplers and plugs, operators can quickly connect or disconnect air pipes, pneumatic tools or equipment, saving a lot of time. Imagine if there were no such connectors, workers would have to make connections by threading or other complicated methods, which would greatly increase the time and complexity of the operation.

Modern quick-connect couplers make operation easier, allowing operators to connect and disconnect by simply pressing a button or rotating the connector. This process is not only fast, but also reduces the possibility of operator errors caused by frequent disassembly and connection. For industries that require efficient operation (such as construction, auto repair, manufacturing, etc.), the quick connection function of couplers and plugs greatly improves work efficiency.

Many high-end coupler systems are designed with features to prevent misoperation (such as locking mechanisms), ensuring that there will be no accidental disconnection while the system is running, further improving operational safety.

3. Improved Safety

Couplers and plugs play a vital role in improving workplace safety. If a high-pressure compressed air system does not have a suitable connection device, it may accidentally disconnect or burst, causing the air tool to lose control or parts to fly out, causing accidents. To solve this problem, many modern couplers are equipped with a variety of safety features, such as automatic locking, push-to-release and anti-misplugging designs to ensure that the connection will not loosen or disconnect in a high-pressure environment.

In some special designs, couplers and plugs are also equipped with a pressure relief function to ensure that excessive pressure will not be suddenly released during the connection and disconnection process, thereby reducing safety risks caused by pressure fluctuations. For example, industrial-grade quick-release couplers are often equipped with anti-pressure relief valves that can control airflow during disconnection to avoid equipment damage and personal injury.

Proper use of couplers and plugs can reduce the occurrence of human operating errors. If operators use traditional connection methods (such as threaded connections), they are prone to air leakage or excessive pressure due to improper installation. The standardized and automated design of couplers and plugs significantly reduces this risk and provides higher safety guarantees.

4. Versatility Across Applications

Couplers and plugs are highly adaptable and can meet the needs of different application environments and industries. Couplers and plugs of various sizes, materials and designs can be selected according to the type of pneumatic system (such as high pressure, low pressure, cold or hot air systems, etc.) and the equipment used (such as air tools, automated machinery, painting equipment, etc.).

For example, some couplers are designed for high-temperature, high-pressure systems and can withstand shock and heat in extreme environments. Other types of couplers are suitable for low-pressure gas or precision instrument connections, and these designs are usually more compact for use in limited spaces. Even complex application scenarios, such as food processing, chemical processing or auto repair industries, will have couplers and plugs designed specifically for that environment.

In a changing working environment, the adaptability of couplers and plugs not only ensures the flexibility of the system, but also improves the versatility and interchangeability of equipment, allowing various tools and equipment to work seamlessly in the same system.

5. Durability and Long Lifespan

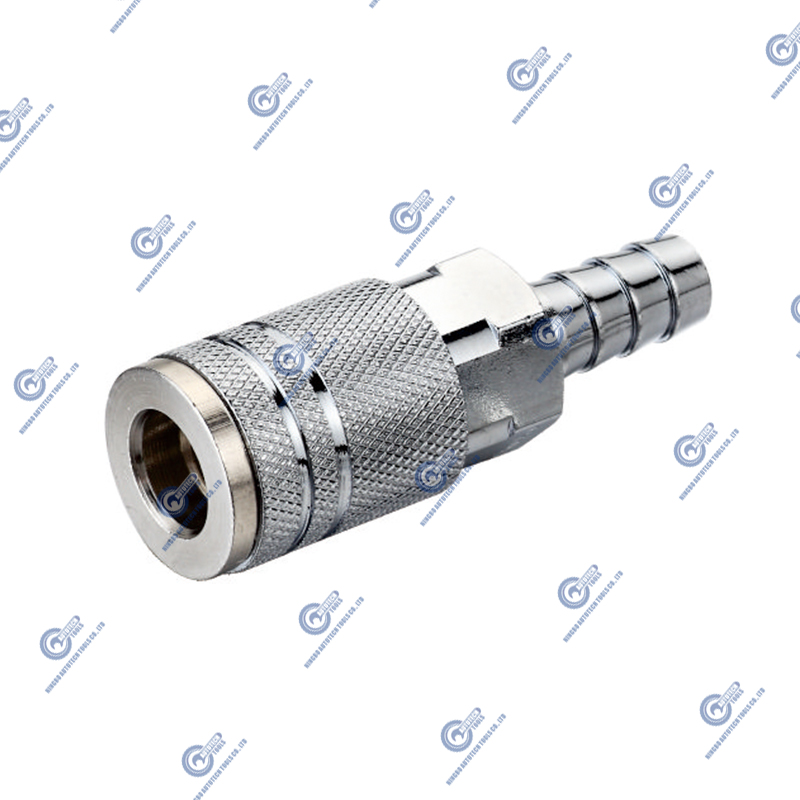

Couplers and plugs are made of durable and corrosion-resistant materials (such as stainless steel, brass or aluminum alloy), which enables them to withstand long-term use and adapt to harsh environments such as high temperature, humidity or chemical corrosion. For pneumatic systems that work under long-term high-load conditions, the durability of couplers and plugs is crucial. If the connectors are frequently worn or damaged, it may cause system downtime or even require the replacement of the entire system, thereby increasing maintenance costs.

High-quality couplers and plugs are precision-machined to maintain their performance over time without the need for frequent replacement. For example, a coupler made of stainless steel will function reliably in the presence of corrosive gases or liquids, without the risk of leaks or loose connections caused by corrosion.

Because these connectors are designed to resist wear, they are not easily damaged even during frequent connections and disconnections. Under normal use, couplers and plugs can outlast many other types of connections, reducing long-term maintenance and replacement costs.