What Are the Different Types of Air Hoses & Fittings and Their Uses?

2026.01.19

2026.01.19

Industry news

Industry news

Air hoses and fittings are fundamental components in any pneumatic system. They serve as the pathway for compressed air to reach tools, machinery, or industrial equipment. Selecting the right type of air hose and fitting is critical for safety, efficiency, and the longevity of your system. Using incompatible hoses or fittings can result in air leaks, pressure drops, or even equipment damage, which may disrupt production or pose safety risks. Understanding the types of air hoses and fittings available helps ensure that your pneumatic system operates reliably and efficiently.

Air hoses come in various materials and designs to suit different applications. PVC hoses are lightweight, flexible, and cost-effective, making them ideal for light-duty use in workshops or home garages. Rubber hoses are known for their durability and high-pressure tolerance, which makes them suitable for heavy-duty industrial applications. Urethane hoses are highly flexible, resistant to kinking, and often used in painting or finishing jobs where mobility and precision are important. Hybrid hoses combine PVC and rubber features to deliver both flexibility and durability, often used in industrial or multi-purpose environments.

| Hose Type | Material | Pressure Rating | Typical Use Cases |

|---|---|---|---|

| PVC Hose | PVC | Low-Medium | Light-duty air tools, general workshop |

| Rubber Hose | Rubber | Medium-High | Automotive shops, heavy-duty equipment |

| Urethane Hose | Polyurethane | Medium | Flexible, kink-resistant, painting jobs |

| Hybrid Hose | PVC/Rubber | Medium-High | Industrial, multi-purpose use |

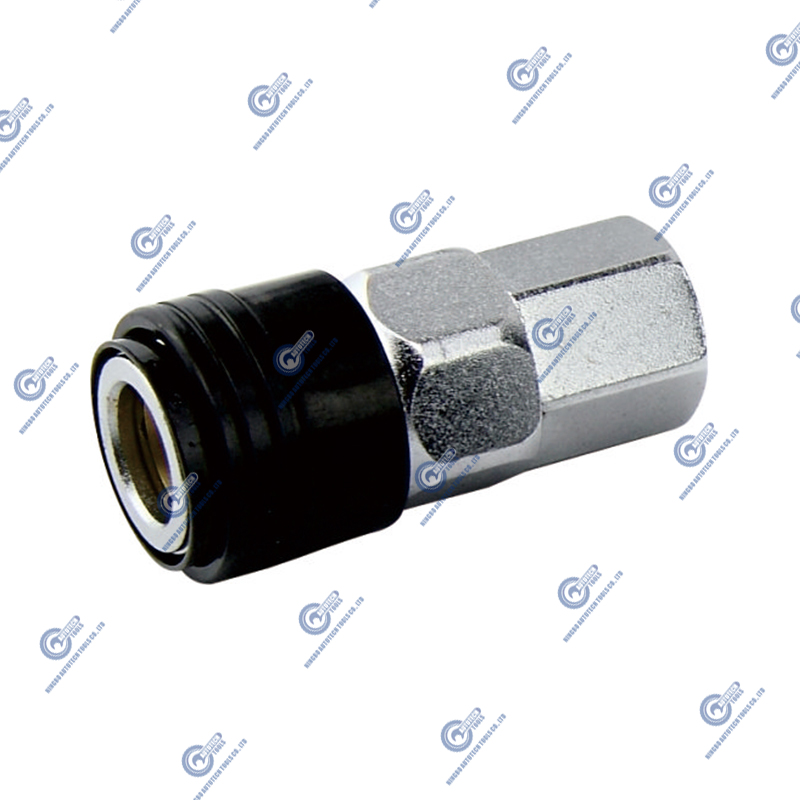

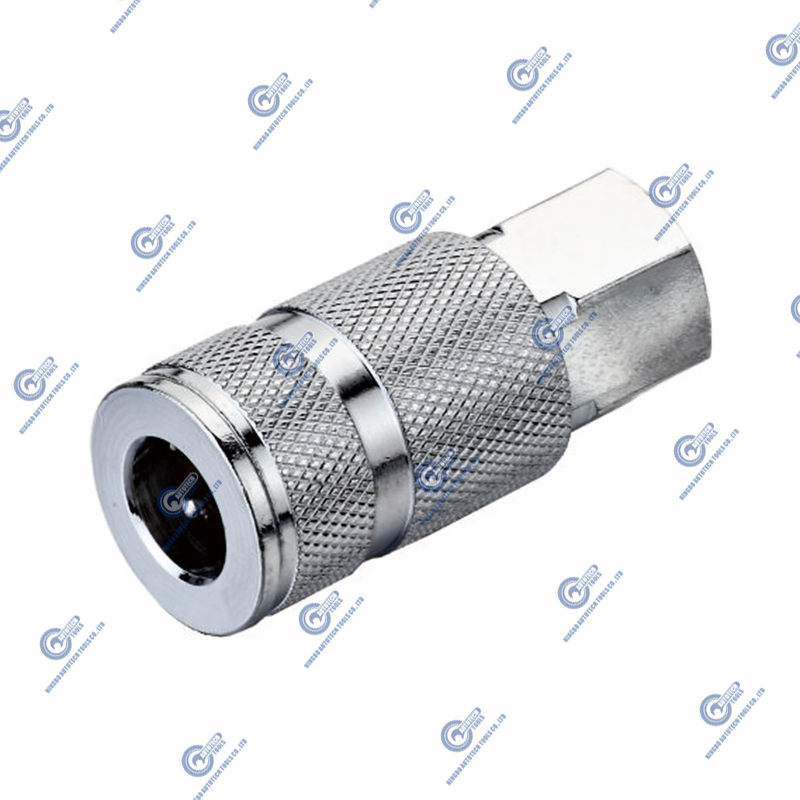

Fittings are equally important and come in various types and materials. Quick-connect fittings allow rapid tool changes, increasing workflow efficiency. Threaded fittings provide a secure and permanent connection, suitable for systems with consistent pressure. Push-to-connect fittings are designed for convenience, allowing hoses to be connected or disconnected without tools, which is helpful in portable systems or temporary setups. The choice of fitting material also matters: brass fittings are corrosion-resistant and durable, ideal for industrial environments, whereas plastic fittings are lightweight and cost-effective for low-pressure applications. Matching the right hose with the right fitting ensures optimal airflow, prevents leaks, and extends the life of both hoses and tools.

Proper selection and maintenance of hoses and fittings significantly impact the performance of a pneumatic system. Always consider the application, pressure requirements, hose length, and environment. Regular inspections for wear, cracks, and leaks, as well as proper cleaning of fittings, will help maintain efficiency and reduce downtime. Combining the correct hose type with an appropriate fitting ensures your system delivers consistent performance while maximizing safety and tool lifespan.

FAQ

Q1: Can PVC hoses be used for high-pressure applications?

A1: PVC hoses are generally suitable for low to medium-pressure systems. High-pressure or heavy-duty applications require rubber or hybrid hoses for safety and durability.

Q2: What advantages do quick-connect fittings offer?

A2: Quick-connect fittings allow fast tool changes without wrenches, saving time and improving workflow efficiency in workshops or industrial setups.

Q3: How should I maintain my air hoses and fittings?

A3: Regularly inspect hoses for cracks or wear, clean fittings, and avoid kinking or stretching the hoses to extend their lifespan and prevent leaks.

Q4: Are metal fittings always better than plastic fittings?

A4: Not necessarily. Metal fittings are more durable and corrosion-resistant, but plastic fittings are sufficient for light-duty or low-pressure applications and are more cost-effective.

References

- Parker Hannifin. Compressed Air Hose and Fittings Guide. Parker.com.

- Gates Corporation. Air Hoses & Fittings: Selection and Maintenance. Gates.com.

- Bimba Manufacturing. Pneumatic Hose and Fittings Overview. Bimba.com.